#Industry News

Tips for choosing the Best UV Cure Adhesive Glue for Glass to Glass

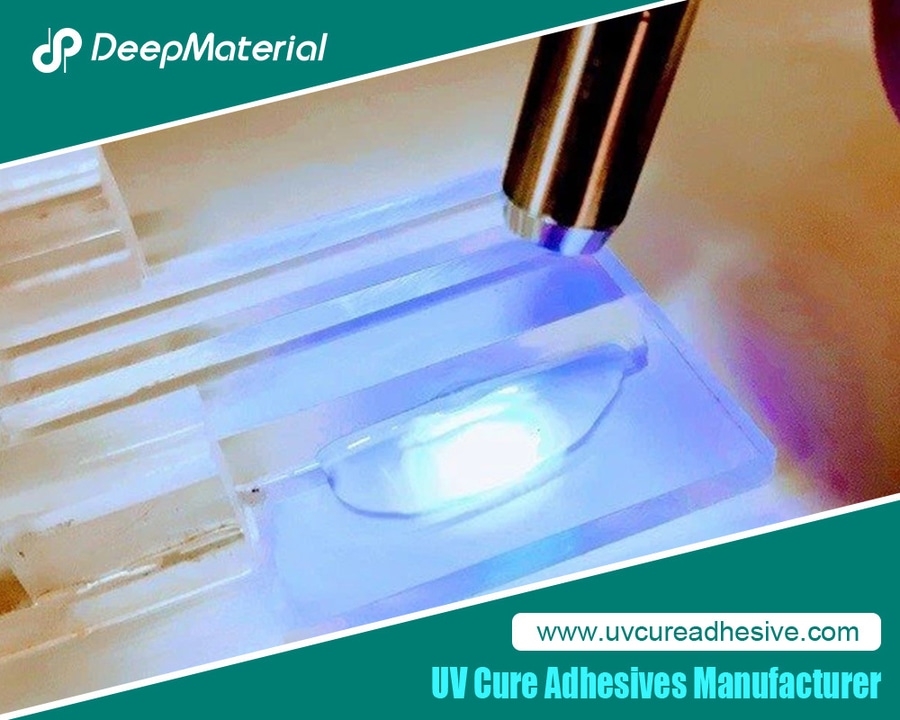

Best UV Cure Adhesive Glue for Glass to Glass Manufacturer

UV cure adhesive glue for glass-to-glass bonding stands as a pivotal solution across various sectors like automotive, electronics, and construction. Its capability to forge strong, durable connections between glass pieces, coupled with its transparency, positions it as the adhesive of choice for projects demanding both aesthetic appeal and robustness. The key to unlocking its potential lies in selecting the optimal adhesive for each specific task, ensuring the bond’s integrity and longevity.

Understanding UV Cure Adhesive Glue for Glass-to-Glass Bonding

At its core, UV cure adhesive glue is engineered for precision in glass-to-glass applications, characterized by its unique composition and curing mechanism. This adhesive blend, rich in monomers, oligomers, and photoinitiators, undergoes a transformative process under UV light exposure. This exposure sets off a photochemical reaction, meticulously designed to secure glass components with unparalleled strength.

The magic begins when UV light meets the adhesive, activating the photoinitiators within. These catalysts kick-start polymerization, a chemical ballet where molecular bonds dance together to form a network of cross-links. It’s this intricate molecular architecture that gifts the adhesive its formidable bond strength, ensuring the glass pieces remain united under various conditions.

Opting for UV cure adhesive glue in glass-to-glass bonding projects not only promises a bond of superior strength but also introduces an element of clarity and finesse to the final assembly. Whether it’s enhancing the structural integrity of automotive glass, ensuring precision in electronic devices, or contributing to the aesthetic and functional aspects of construction, the right UV cure adhesive glue turns glass bonding from a mere step in the manufacturing process into a cornerstone of quality and reliability.

Advantages of UV Cure Adhesive Glue for Glass-to-Glass Bonding

UV cure adhesive glue revolutionizes the way glass surfaces are bonded, providing a slew of benefits that enhance both DIY projects and professional applications alike. Here’s why it stands out:

Unmatched Strength and Durability

The most striking feature of UV cure adhesive glue is the formidable chemical bond it forms between glass surfaces. This bond isn’t just strong; it’s designed to withstand environmental onslaughts like moisture, heat, and various chemicals. Such resilience ensures the bond remains steadfast over time, offering dependability and longevity unparalleled by traditional bonding methods.

Rapid Curing Time: A Leap in Productivity

Speed is of the essence with UV cure adhesive glue, boasting a curing time that’s nothing short of lightning-fast. Where conventional adhesives lag, requiring hours or even days to cure fully, UV cure glue dashes ahead, setting in seconds to minutes under UV light. This brisk pace not only propels manufacturing productivity skyward but also minimizes risks of damage or contamination during the curing phase, promising a pristine finish.

Simplified Process: No Clamping, No Heating

The innovation doesn’t stop with speed. UV cure adhesive glue simplifies the bonding process by eliminating the need for clamping or heating—steps that are staples with traditional adhesives. This straightforward approach allows for quicker project completion and is especially beneficial for materials sensitive to heat or pressure. Its versatility extends across various materials, making it a universal bonding solution for projects involving plastics, metals, and, of course, glass.

Aesthetic Excellence: Clear and Transparent Finish

Aesthetic integrity is paramount in many projects, and UV cure adhesive glue excels here as well. It dries clear, maintaining the natural beauty of glass without compromising transparency. The absence of visible residue or marks ensures that the final product not only holds together securely but also looks impeccable. Ideal for applications where a flawless finish is non-negotiable, this adhesive supports the creation of work that is both structurally sound and visually appealing.

In essence, UV cure adhesive glue for glass-to-glass bonding is not just a bonding agent; it’s a game-changer. Its strength and durability, coupled with a fast curing time, ease of use, and clear finish, make it an attractive option for a wide range of industries. Whether in the realms of automotive, electronics, construction, or decorative arts, this adhesive promises to deliver superior results, blending functionality with finesse.

Factors to Consider When Choosing UV Cure Adhesive Glue for Glass to Glass Bonding

Choosing the right UV cure adhesive glue for bonding glass surfaces is a nuanced process, requiring careful consideration of various factors to ensure the integrity and aesthetics of the final product. Here’s what to keep in mind:

Understanding Glass Types

Different glass types, from tempered to coated, boast unique compositions and treatments affecting their bonding capabilities. A one-size-fits-all approach won’t cut it; instead, choose an adhesive that aligns with the specific properties of the glass you’re working with. Whether you’re dealing with the enhanced strength of tempered glass or the specialized treatments of coated varieties, selecting the right adhesive is pivotal for a secure and lasting bond.

Surface Preparation Necessities

The adhesion process begins long before the adhesive is applied—it starts with surface preparation. Understanding the preparation required, from cleaning with specific solvents to applying a primer, is crucial. Skipping or improperly executing this step can lead to weakened bonds and project failure. Ensure the adhesive you choose is compatible with the pre-treatment process for optimal bonding performance.

Evaluating Bond Strength and Durability

The strength and longevity of the bond are paramount. Assess the demands of your project to determine the necessary level of bond strength. High-stress applications will necessitate a more potent adhesive, while lighter tasks may afford more flexibility in choice. Additionally, consider the adhesive’s durability, especially in the face of environmental stressors, to ensure the bond withstands the test of time.

Curing Time and Process Compatibility

The curing time can greatly influence the efficiency and outcome of your project. Select an adhesive whose curing time and process align with your production needs, whether that’s a rapid set for high-throughput environments or a slower cure for intricate assemblies. The right choice here ensures seamless integration into your workflow, enhancing productivity without sacrificing quality.

Accounting for Temperature and Humidity

The environment plays a crucial role in the curing process. Select an adhesive tailored to thrive in your specific temperature and humidity conditions to avoid compromised bonds or extended curing times. This foresight ensures the adhesive performs as expected, maintaining its integrity and bonding strength under the conditions it will face.

By meticulously considering these factors, you’re equipped to select a UV cure adhesive glue that not only meets the technical requirements of glass-to-glass bonding but also complements your workflow, ensuring a successful and efficient project completion.

Final Thoughts

In conclusion, the journey to secure a resilient and lasting glass-to-glass bond hinges on selecting the right UV cure adhesive glue, a decision informed by a thorough understanding of the specific project needs. Key considerations include the type of glass involved, requisite surface preparation, desired bond strength, appropriate curing time, and prevailing environmental conditions.

Equally important is adhering to safety protocols while handling UV cure adhesive glue and employing proper application techniques to ensure optimal outcomes. By thoughtfully navigating these factors and embracing best practices, one can master the art of glass-to-glass bonding across a variety of applications, achieving results that are as durable as they are aesthetically pleasing.

For more about choosing the Best UV Cure Adhesive Glue for Glass to Glass, you can pay a visit to DeepMaterial at https://www.uvcureadhesive.com/ for more info.