#Industry News

JONO’s Recyclable Waste Solution

Chengdu Urban Resources Sorting Center Project

Project Overview

This project occupies an area of 32 acres and has a total investment of 80 million yuan. It is capable of processing an average of 100 tons of bulky waste and 800 tons of C&D waste per day, with an annual disposal capacity of 300,000 tons. It adopts "environmental protection + waste sorting + recycling resources" as its core and has pioneered the national sorting center and the integration of two networks for joint disposal.

Processing Process

The entire process of waste disposal:

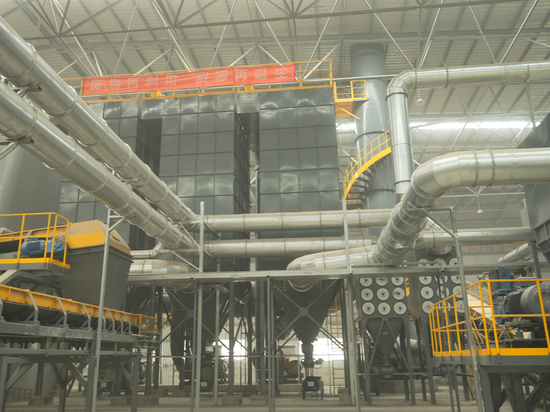

The C&D waste enters the belt device via the feeding port and undergoes physical screening in the equipment. The entire waste treatment process follows the "breaking first and screening later" workflow. After being treated by the ladder screen, compound screen, and wind selection equipment, six or more types of recycled resources can be screened out, such as wood, plastic, and fiber.

The end product is 0-5mm and 5-16mm recycled aggregate, rubble, and light combustible material. The recycled aggregate can be used for road paving and subgrade in municipal engineering, and the light combustible material can be used for cement kiln incineration power generation, bringing considerable economic benefits.

Equipment Introduction

In this project, the following equipment was mainly used:

Stepped screen:

Its function is to classify the renovation waste by size. The screened substance is large-sized interference material. After falling into the cargo compartment, it will be crushed again and enter the sorting system. Click the link for more information about this product.

https://jonogroup.en.made-in-china.com/product/FxvUSbWhCEpk/China-Stepped-3D-Screen-With-Reasonable-Structure-Design.html

Multi-layer Composite Screen

This versatile composite screen can be applied for separating C&D waste, recyclables, slag, and etc. It is used to classify soil in construction waste. After the sorting process, it will enter the sorting equipment.

Click the link for more information about this product.

https://www.instagram.com/reel/C9LtM5Etaqx/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==

Vibrating Screen

Workers are sorting various materials such as wood, fibers, plastics, etc. on the machine, while the remaining bricks and stones are then sent to a circular vibrating screen to separate out two different sizes of aggregate: 0-5mm and 5-16mm.

Click the link for more information about this product.

https://jonogroup.en.made-in-china.com/product/MxvYBHWUaQRo/China-Convenient-And-Safe-Vibrating-Screen.html

Conclusion

As a key project being actively promoted by Wuhou District, Chengdu City, it has made an important contribution to the sustainable development of Sichuan Province.