#Industry News

In-depth Understanding of Through-Hole PCB and Its Applications

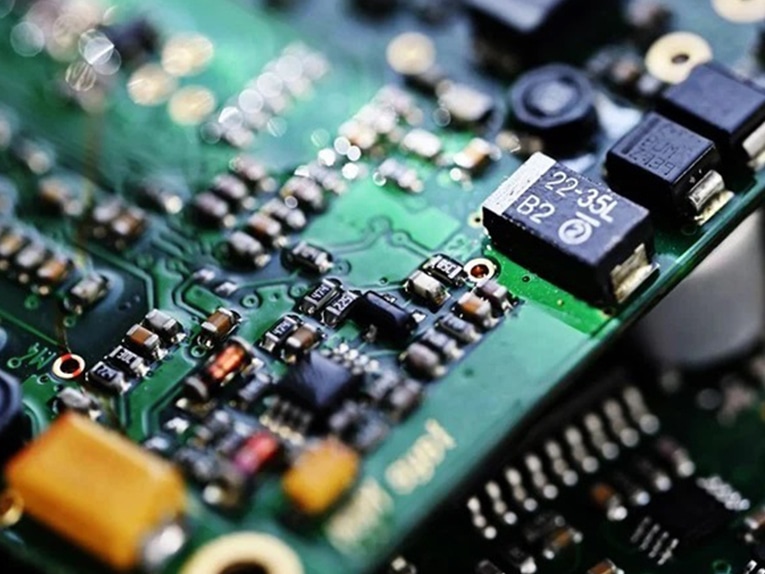

Through-Hole PCB and Applications

Through-Hole Printed Circuit Board (Through-Hole PCB) is a technology that involves inserting electronic component leads into plated holes in a circuit board and soldering them for a secure connection. While Surface Mount Technology (SMT) has become increasingly popular, through-hole PCB still maintains distinct advantages in certain fields.

1. Types of Components:

Axial Components: Leads extend from both ends of the component and need to be inserted into different positions on both sides of the PCB.

Radial Components: Leads extend from the same side of the component, typically shorter, with more concentrated mounting positions.

2. Through-Hole PCB Assembly Process:

Design and Prototyping: Circuit design is completed, generating the PCB layout. Afterward, manufacturers create prototypes to ensure design accuracy and feasibility.

Drilling: Based on the design requirements, holes are drilled into the PCB, which can penetrate the entire board and are suitable for single or multilayer boards.

Plating: To connect the component leads to the internal conductive layers of the PCB, copper is usually plated inside the holes to ensure proper electrical connectivity.

Component Insertion: Leads are inserted into the through-holes, either manually or with automated equipment.

Soldering: Using wave soldering or manual techniques, component leads are soldered to the PCB pads for a stable and reliable connection.

Testing and Inspection: After soldering, functional and electrical testing is performed to ensure all connections are sound and components work properly.

3. Advantages and Disadvantages of Through-Hole PCB:

Advantages:

Strength and Reliability: The component leads pass through the PCB and are soldered on the opposite side, providing stronger connections than SMT, especially in applications that require mechanical stress, like industrial equipment and automotive electronics.

High Temperature and High Voltage Tolerance: Through-hole PCB performs well in extreme environments, handling high temperatures and voltages, making them suitable for military and aerospace applications.

Suitable for High Power Circuits: Through-hole technology is ideal for mounting high-power components such as power modules and transformers, as the leads provide strong electrical connections and heat dissipation, reducing the risk of overheating.

Reliable Electrical Connections: Leads passing through the PCB and being soldered on multiple layers ensure stable electrical connections, reducing failure over time and increasing circuit reliability.

Ease of Manual Assembly and Repair: Components on through-hole PCBs are easier to manually solder, replace, and repair, making them ideal for electronic devices requiring regular maintenance and simplifying troubleshooting.

Ideal for Prototyping and Small-Batch Production: Through-hole PCBs are more suitable for prototyping and small-scale manufacturing due to their more relaxed assembly requirements, enabling engineers to quickly test and adjust designs.

Disadvantages:

Limited Density: Compared to SMT, through-hole PCB components occupy more space, leading to lower circuit density. This limits integration and makes it unsuitable for modern, compact electronic devices.

Higher Production Costs: The production process for through-hole PCBs is more complex, especially with drilling and plating for multilayer boards, increasing manufacturing time and cost.

Challenging Automation: While automation for through-hole components has improved, soldering remains difficult to fully automate. Compared to SMT, through-hole assembly requires more labor or complex machinery, reducing production efficiency.

4. Applications of Through-Hole PCB:

Although through-hole technology has been gradually replaced by SMT in many consumer electronics, it remains crucial in applications requiring strong electrical connections and mechanical stability, such as:

Industrial Equipment: PCBs in the industrial sector often face higher power, heat, and mechanical stress. Through-hole PCBs, with their robust connection structures and heat dissipation properties, are widely used in power supplies, controllers, and inverters.

Power Circuits and Connectors: Through-hole technology is ideal for high-current and high-power circuits. Connectors, which require frequent plug-in and unplugging, also typically use through-hole soldering to ensure long-term stability and reliability.

Prototyping and Testing Boards: During product development and testing, through-hole PCBs remain a favorite due to their ease of manual handling, adjustment, and repair, making them the go-to option for developers.

As a professional electronics manufacturing service provider with more than 20 years of experience, whether it is SMT or through-hole PCB, TECOO can provide the best solutions according to different application scenarios. We have advanced equipment and mature technology, and are committed to perfectly integrating technology with customer needs to ensure that every project reaches the highest standards and meets customer expectations.