#Industry News

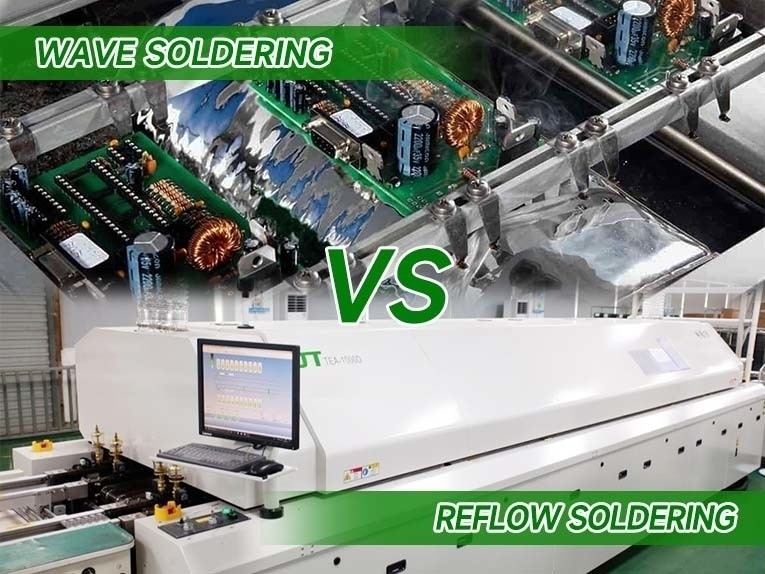

What Is The Difference Between Reflow Soldering And Wave Soldering?

Difference Between Reflow Soldering And Wave Soldering

What is reflow soldering?

Reflow soldering refers to the electrical interconnection of the pins or soldering terminals of electronic components pre-mounted on the pads with the pads on the PCB by heating and melting the solder pre-coated on the pads, so as to achieve the electrical interconnection of the electronic components. The purpose of welding components on the PCB board. Reflow soldering relies on the action of hot airflow on the solder joints. The colloidal flux physically reacts under a certain high-temperature airflow to achieve SMD welding; so it is called "reflow soldering" because the gas circulates in the welding machine to generate high temperature to achieve welding. Reflow soldering is generally divided into preheating zone, heating zone and cooling zone.

What is wave soldering?

The molten solder (lead-tin alloy) is sprayed into the solder wave required by the design through an electric pump or an electromagnetic pump, so that the printed board pre-installed with components passes through the material wave to realize the soldering terminal or lead of the component. Soldering the mechanical and electrical connection between feet and printed board pads. The wave machine is mainly composed of a conveyor belt, a flux adding area, a preheating area and a wave soldering furnace. Its main material is solder strips.

The difference between reflow soldering and wave soldering

1. Wave soldering is when molten solder forms a solder wave to solder components; reflow is when high-temperature hot air forms reflow molten solder to solder components.

2. Different processes: Wave soldering requires spraying flux first, and then goes through preheating, soldering, cooling zone, and reflow soldering. There is already solder before the PCB is put in the furnace. After soldering, the coated tin tone is just melted for soldering. Wave soldering When the PCB is put into the furnace, there is no solder. The solder wave generated by the welding machine spreads the solder on the pads that need to be welded to complete the welding.

3. Reflow soldering is suitable for chip electronic components, and wave soldering is suitable for pin electronic components.