#Product Trends

Auto Lights | Tederic OptiSure multi-layer thick-walled lens injection molding solution

Tederic OptiSure™ multi-layer injection thick-walled lens solution

Headlamps with lens heads are evenly bright and more penetrating than those with conventional heads, so they have greater penetration in both rainy and foggy weather, thus allowing oncoming traffic to receive the light message first and avoid accidents.

In other words, a clearer view means greater safety.

Thick-walled lenses for headlamps have the most stringent requirements in terms of optical quality, as they are a matter of driving safety and need to be free from light diffusion, warpage, and perfect surface properties.

For a typical headlamp lens with a thickness of 30 mm, a standard injection molding process requires a cycle time of at least 20 minutes to complete a single mold run - a cycle time that is unrealistic for injection molding economics.

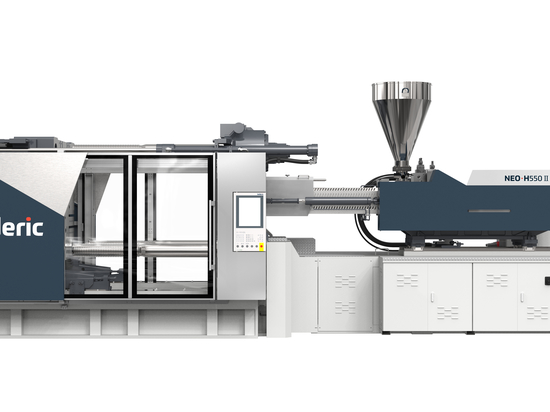

Tederic OptiSure™ multi-layer injection thick-walled lens solution uses a model of Tederic NEO·E electric injection molding machine equipped with OptiSure™ multi-layer injection technology and a fully automated system. The optical quality of thick-walled lenses is met while significantly reducing production cycle times and increasing the economic efficiency of the production process.