#Industry News

CellSure® Micro-Foaming Technology: Enhancing Automotive Lightweighting

The global automotive industry is rapidly moving towards electrification. Traditional "plastic instead of steel" technology has achieved remarkable results in automobile lightweighting, but further weight reduction is still a major challenge.

The global automotive industry is rapidly moving towards electrification. Traditional "plastic instead of steel" technology has achieved remarkable results in automobile lightweighting, but further weight reduction is still a major challenge.

Faced with challenges, automotive lightweighting involves improving the energy efficiency of EVs and a comprehensive consideration of cost and technology.

Relevant data show that by 2025, the proportion of lightweight materials used in automobiles is expected to exceed 47%, helping the body to reduce weight by 50%. (source Lucintel)

As an industry innovator, NEO·H550II IMM takes CellSure® micro-foaming technology as the core, which has injected new vitality into the lightweight application of automotive structural parts.

01. CellSure® micro-foaming technology

Meet the need for lighter, more durable, and more compression-resistant automobiles.

Weight reduction in general automotive plastic structural parts has become a trend, but how can weight be reduced while improving durability and compression resistance? CellSure® micro-foaming technology provides the solution.

This injection molding process reduces weight and enhances the toughness of parts, increasing the strength of structural parts by 10%-20%. This technological breakthrough allows automotive structural parts to achieve an ideal balance between lightweight, safety, and durability, giving new possibilities for lightweight of EV.

02. How does CellSure® micro-foaming technology work?

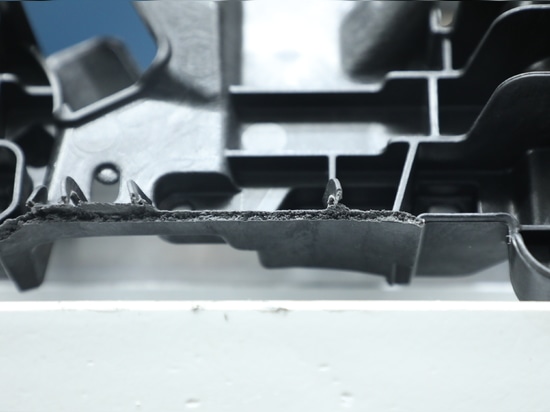

CellSure® micro-foaming technology uses a mixture of nitrogen and plastic injected into the mold to nucleate and grow bubbles during a sudden drop in pressure, creating a uniform cellular structure inside the product.

Highlights:

1.Lightweight: By ensuring the original mechanical properties, the product's weight can be reduced by up to 15%.

2.High durability: The honeycomb structure makes products of the same quality more durable and resistant to compression

3.Low clamping force requirements: effectively reduce production energy consumption, shorten molding cycle, improve productivity and efficiency

03. Automobile structural parts solution

Cost reduction and efficiency increase, dual improvement of efficiency and quality

Regarding cost control, NEO·H550II IMM reduces cost and efficiency for customers by reducing raw material consumption and clamping pressure. At the same time, the service life of the mold is prolonged, and the overall economy of the production process is further optimized.

Notably, the weight reduction scheme of automobile structural parts is equipped with tederic closed-loop control technology. The main body of the equipment is equipped with a high-precision displacement sensor to monitor the mold's parallelism in real-time. In addition, the booster cylinder is equipped with four independent proportional servo valves to adjust the precision of clamping force and mold parallelism dynamically.

After injection, the mold is slightly opened, and the micro-opening accuracy of ±0.01mm can be realized.

Highlights:

1.Lightweight of the automobile: CellSure® micro-foaming technology for up to 15% weight reduction.

2.High economic benefits: Reduce raw material consumption and mold clamping pressure, prolong the service life of the mold, reduce costs, and increase customer efficiency.

3.Precision: Tederic closed-loop control technology, real-time monitoring and adjustment of mold parallelism, micro-opening accuracy up to ±0.01mm to ensure product qualification rate.

·Cavity Qty: 2

·Material: PP+30%GF

·Cycle: 70s

·Weight: 325g, weight loss 10%

In this lightweight innovation journey, we see the vigorous development of the new energy automobile industry and the rise and responsibility of China's Intelligent Manufacturing in the global automobile industry.