#Product Trends

Automotive interiors | Tederic DecoSure IMD technology holds great promise

With DecoSure™ technology Tederic has meet the upgrading of automotive interior products and caters to the design needs of high-end brands.

IMD technology is a new plastic decoration process technology that can make different special surface effects, improve the quality and added value of products, and at the same time, broaden the scope for product innovation; widely used in communication, electronics, and home appliances, automotive and other industries.

The technology uses either thermo- or high-pressure forming to stretch the transferred film, cut out the insert according to the product's shape, and then place the insert precisely in the injection mold cavity for one-piece injection molding to achieve a decorative and functional effect.

With DecoSure™ technology and a wealth of experience in the automotive industry, Tederic has provided mature, leading-edge interior solutions for new energy vehicle leaders such as BYD and Tesla, as well as leading car companies such as Mercedes-Benz and BMW, ensuring that automotive interiors are both functional and decorative.

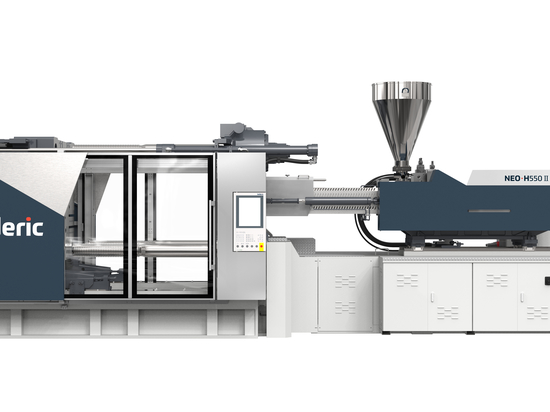

The head of production at a large listed automotive parts company said that Tederic was a perfect alternative to high-end imported equipment in terms of stability, yield, and production efficiency, with a 19% reduction in energy consumption! The DecoSure™ in-mold decoration technology has brought huge economic benefits, and dozens of Tederic's NEO·T series and NEO-H machines have been purchased for the production of interior trim parts.

Tederic is committed to providing customized, cleanroom-friendly, one-stop professional solutions for customers in the automotive industry. To learn more, please stay tuned.