#Trade Shows & Events

Tederic electric injection molding machine appeared in MOLDPLAS 2022, innovative technology to enable green production

In the context of the global two-carbon trend and the energy crisis.

In the context of the global two-carbon trend and the energy crisis, the high efficiency and energy saving motor can improve production efficiency and reduce the consumption of resources and energy, which has become the first choice of many plastic manufacturers in Europe.

The four-day MOLDPLAS 2022 was held at the Battaglia Battle Exhibition Center in Portugal on November 9, local time. It is reported that MOLDPLAS is a well-known mold and plastic industry exhibition and trade fair in Portugal.

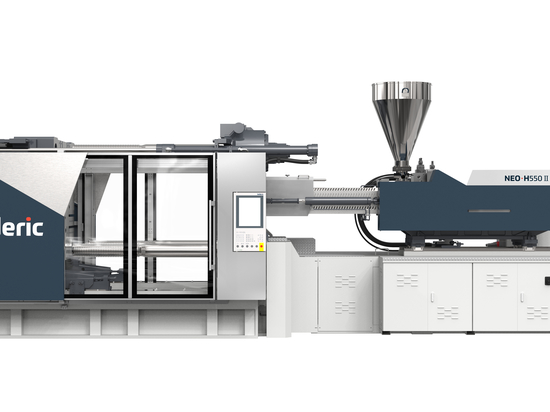

Plastic packaging, as one of the largest industries in the field of plastic application, is growing in scale and speed. In the current severe energy situation, Tederic takes customer value as the core, and presents its flagship products - popular electric models DE.85, NEO·E208c, NEO·E258c and the overall solution. Committed to build sustainable development with global customers.

Efficient and stable machine performance and leading technology advantages became the focus of the site. More than 100 customers of daily necessities, packaging, automobile and other industries visited the booth of Tederic for in-depth conversation.

So why does Tederic electric packaging plane attract so much attention?

Low energy consumption. Using the most advanced energy recovery system, it can save 8%-15% more energy than the traditional motor, which can reach the highest energy saving grade 9+ of the European injection molding machine standard.

High efficiency. Motor has faster dry cycle, standard linkage function, product molding cycle is greatly shortened, higher production capacity.

Low cost. No oil temperature leakage and other common hydraulic interference, equipment parameters are stable all year round; Small number of parts, easy troubleshooting, reduce maintenance costs.

More sophisticated. Injection position repetition accuracy up to 0.01mm, high rate of fire, high pressure, to ensure that the product dimensions meet the requirements of high-end European market.

Much cleaner. Meet ISO Class 8 (Class 10w) clean room production environment requirements.

Tederic can provide 265 tons to 800 tons of electric packaging machine, the maximum rate of fire 500mm/s, higher efficiency, better performance, for customers to create sustainable value.

After years of development, Tederic has continuously increased its investment in R&D and marketing, and established and operated its overseas subsidiary in Portugal at the end of 2018. It has also become the first stop of Tederic's global layout, the European sales and service center. Equipped with more than 50 people sales, technical and service team and parts warehouse, pull rod, screw, heating ring, valve, controller and other accessories sufficient, can provide fast, convenient, quality service.

At present, it has become the largest injection molding machine brand in the market share of Portugal, and has accumulated a large number of high-end customers in the automotive and packaging industries in Europe.

In the future, Tederic will continue to rely on its Portuguese subsidiary, link to advanced European technologies, make full use of years of accumulated green production experience, energy saving and consumption reduction technology, and export more intelligent overall injection molding solutions in line with low-carbon concept to global customers and partners, and jointly shape a sustainable future.

The exhibition continues today, if you are unable to go to the site, please contact us directly for more information!