#Product Trends

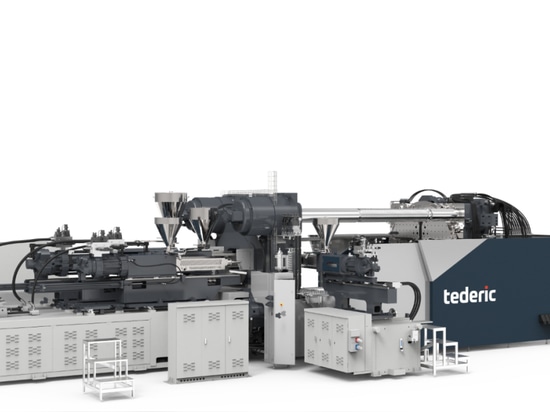

China's first super - large - tonnage jet molding machine to market

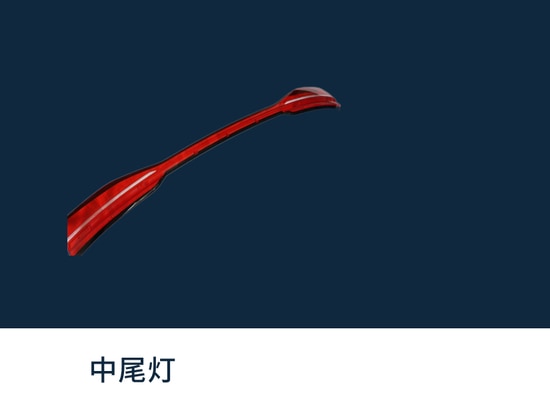

With the development of automobile industrialization, as the core parts of automobiles with strong consumption driving force, the design of headlights should not only meet the basic lighting function, but also take into account the creation of atmosphere and improve the identification of automobiles.

With the development of automobile industrialization, as the core parts of automobiles with strong consumption driving force, the design of headlights should not only meet the basic lighting function, but also take into account the creation of atmosphere and improve the identification of automobiles.

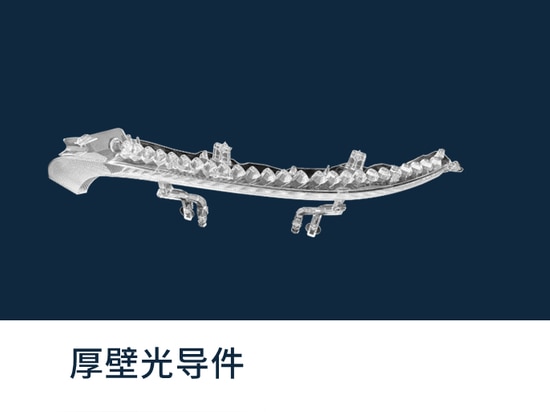

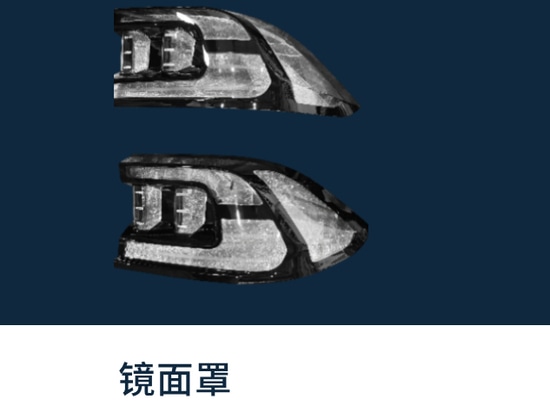

Under this trend, the design of the structure of the headlight parts is more complex and irregular, which poses new challenges to the design of the screw of injection molding equipment and the control of injection accuracy. And through the taillight, headlight mask and other large size injection requires a larger mold size, which requires a larger mold space.

Therefore, it is particularly important to choose stable, high precision and suitable injection molding equipment.

Tederic launched the first large tonnage vertical rotary jet forming machine in China

With years of technical accumulation and competitive advantages in the field of multi-maTederical injection molding, Tederic has continued to break through a number of "stuck neck" technical bottlenecks.

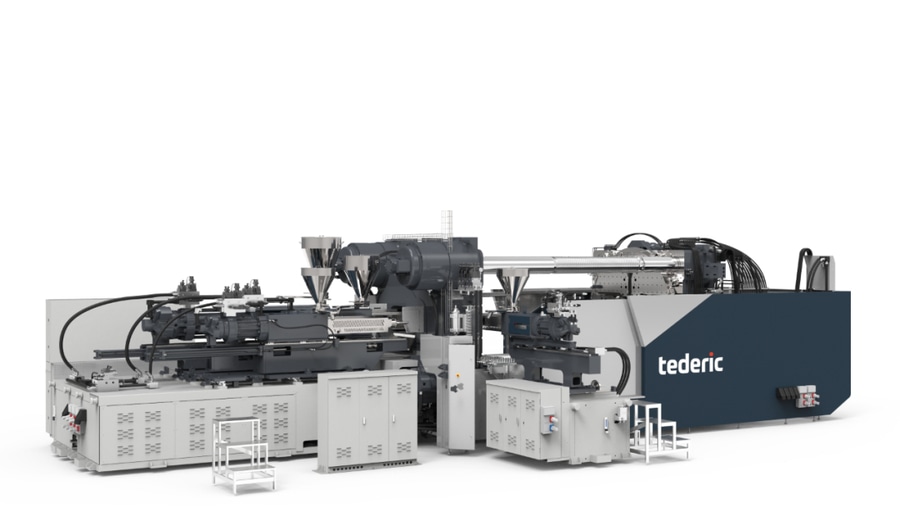

In view of the development trend of new energy vehicle headlights, Tederic takes the lead in launching super tonnage vertical rotary disc radiant molding machine, which is one of the few domestic enterprises with R&D and manufacturing capability of super tonnage multi-component injection molding machine.

Recently, Tederic 2320-ton multi-component injection molding machine has been successively entered into domestic auto parts manufacturing factories and put into production. Its excellent performance is widely praised by customers. As the first large-tonnage vertical turntable radiating molding machine in China, its super-large vertical turntable has a diameter of 2.5 meters, which is suitable for the production of large-size headlights such as through-type headlights, thick-wall light guides, mirror masks and so on.

Based on the diversified needs of customers, Tederic has provided a number of complete integrated intelligent lighting solutions, effectively achieving high quality, customized, diversified lamp production needs.

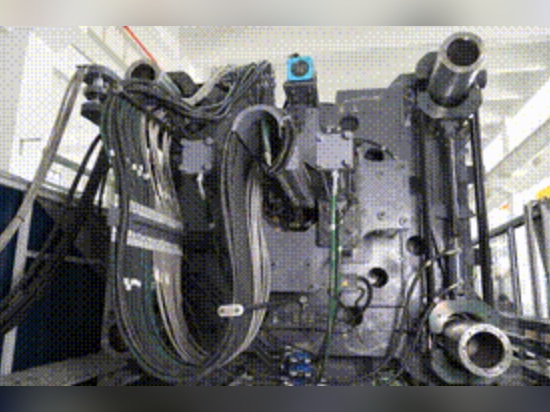

▲ Customer site

Product highlights

More stable:

Injection parts are made of high quality screw, injection proportional valve control, the product weight repetition accuracy is up to 0.3%. Coupled with Tederic SpinSure® V-vertical rotary table technology, the rotary table servo control precision up to 0.01°, easy to handle high quality injection molding headlights.

More flexible:

With Terry ™ MultiMold Master Multi-color injection molding technology, the launcher can be driven according to combination, four injection angles can be laid out freely, and the modular launcher structure can be flexibly formed into more than 30 combinations to provide customers with diversified solutions.

More intelligent:

Free programming for customers to provide customized requirements, mold temperature control is more stable.

More energy saving:

High performance hydraulic servo system, low heat, high efficiency, large overload capacity, fast response, pressure fluctuation of ±0.6bar, speed fluctuation of 16rpm, help customers to reduce cost and increase efficiency.

More efficient:

Diagonally balanced fast shifter cylinder, open and close the mold faster, effectively shorten the cycle.

▲ Torque tube processing device for water, oil, electric pipeline efficient positioning, to avoid the deformation of the machine pipeline in the process of operation, improve product production efficiency.

As the pioneer of domestic plastic machinery enterprises, Tederic will use new products and new technologies to accelerate research and development and application, provide users with more one-stop intelligent solutions, and promote the new energy automobile industry to run out of the "acceleration"!