#Trade Shows & Events

【2023CHINAPLAS】 Core technology expands the new boundary of intelligent injection molding in the field of new energy vehicles

On April 17th, 2023CHINAPLAS opened at Shenzhen International Convention and Exhibition Center.

On April 17th, 2023CHINAPLAS opened at Shenzhen International Convention and Exhibition Center.

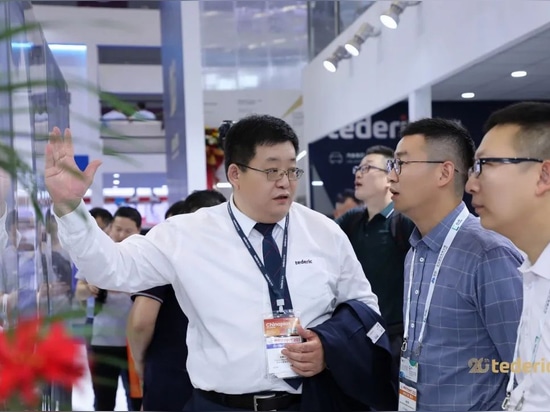

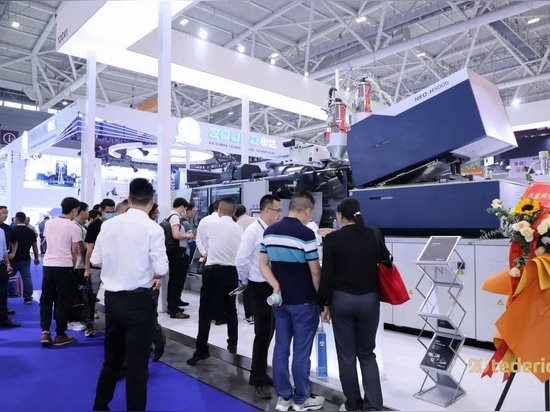

This year's 2023CHINAPLAS coincides with Tederic's 20th birthday. The great crowds of visitors and the endless stream of new and old customers visiting the reception area are the best response to Tederic's 20th birthday!

At the beginning of the exhibition, the innovative solutions of multi-materical molding for the two major new energy automobile industry amazed the audience. Tederic's core technology advantages accumulated over many years in the field of new energy vehicles will be presented to the site visitors at one time.

Let's walk into Tederic's booth

Unlock the scene wonderful moment!

▲ Swipe to see more pictures

01 Intelligent injection molding pioneer

As a one-stop intelligent injection molding provider, Tederic deep cultivation plastic machine industry for 20 years. 2023CHINAPLAS, Tederic focuses on "innovation is omnipotent" and brings the latest research and development achievements of "technology up" strategy -- CoinSure™ Injection Compression Molding Process and OptiSure™ Multi-layer Thick-wall lens Injection Molding Application.

The two solutions fully integrate the advantages of Tederic's intelligent injection molding technology, break the international "technical barriers" and solve a number of "bottleneck" key problems, give play to the highest efficiency of "intelligent plastic".

In the customer's praise, Tederic once again demonstrated the strong technical strength and forward-looking development concept of intelligent injection molding to global users.

02 New energy vehicle injection molding leader

In recent years, under the support of the "double carbon" policy, new energy vehicles are more and more recognized and favored by the majority of consumers. As one of the earliest plastic machinery enterprises in China to make efforts in the new energy automobile industry, Tederic quickly transformed its technological advantages into product advantages and launched a series of large-scale multi-materical injection molding machines that are well received by users.

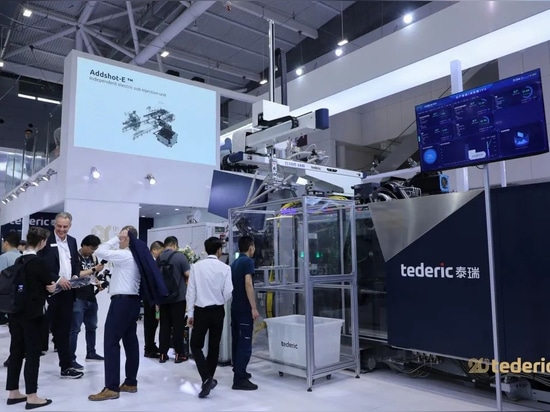

This demonstration program of CoinSure™ injection compression molding process technology, which is provided by NEO·M1120s horizontal rotary multi-component injection molding machine, attracted many visitors to stop and watch, and deserved to be the star product of the exhibition hall.

The scheme improves the optical properties of plastic products, integrates molding, meets the special production needs of complex surfaces, and helps new energy vehicle brands realize the freedom of product design.

▲CoinSure™ Injection molding Compression molding process demonstration program

As Tederic's advantage products, NEO·M series large multi-materical injection molding machines have covered the whole 1120t-3520t, and its vertical rotary multi-materical injection molding machines take the lead in breaking through the industry's largest rotary diameter of 2800mm.

More than the head auto parts manufacturing enterprises to provide highlighter external column, headlamp, headlamp lamp shade, tail lamp shade and other headlight optical parts high-quality production of injection molding solutions.

▲ Tederic multi-materical molding innovative solutions in EV industry

03 Technology integration

Because of the initiative to embrace the future of new technology and active layout, Tederic has gained a head start in the industry market environment.

As a major innovator of new energy vehicle intelligent injection molding technology, Tederic's technical strength can be demonstrated by the world's first OptiSure™ multi-layer thick-wall lens injection molding solution. The solution adopts layered injection molding and external cooling, and uses rotary mold core technology to reduce the single-layer shrinkage, and can produce four thick-walled optical lenses in 200 seconds, increasing production efficiency by 30%.

▲OptiSure™ multi-layer thick-wall lens injection molding solutions

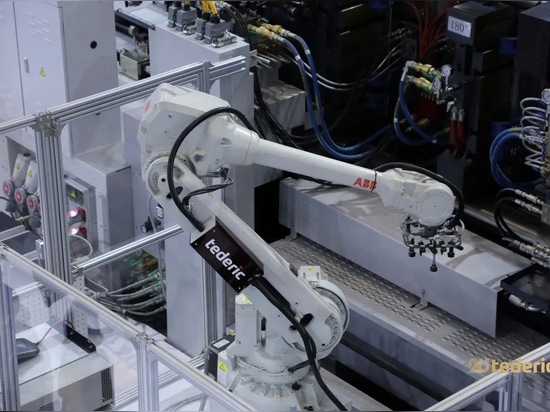

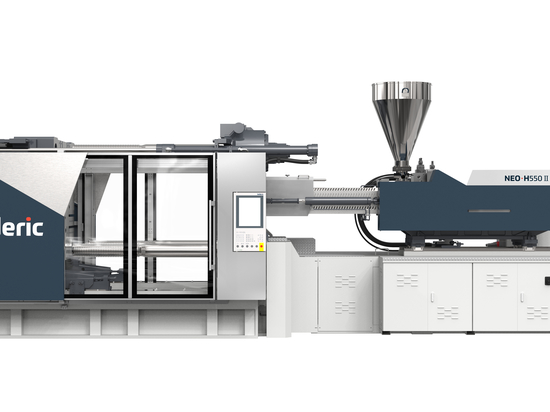

Tederic's technical strength is reflected in the innovative elements in the one-stop intelligent injection molding demonstration scheme, but also in the technical details of the product. Exhibition machine NEO·H500b rotary mold core multi-layer injection molding machine pure two wide plate mold locking structure and Angle hinged layout, compared with the right Angle arrangement mode, the floor area is reduced by 30%.

The injection accuracy of the electric platform can reach less than 0.1%. Rotary core servo drive, multi-station high-precision rotation, to ensure precise machining of products. Rotary mold core module block design can be completely disassembled, flexible for mold application.

We can expect that Tederic's beneficial exploration in the field of injection molding of new energy vehicles will produce more fruitful technical achievements!

The exhibition is in full swing. Look forward to your visit to Tederic Booth: 12C41! Energy vehicle field intelligent injection molding new boundary