#Industry News

The Powerful Combination of Tederic and Li Auto

EV are the main direction of the transformation and upgrading of the global automobile industry and the green development, and they are also the strategic choice for the high-quality development of China's automobile industry.

As a well-known EV manufacturer in China, only in May 2023, Li Auto sales far exceeded traditional luxury brands and other new power brands. With 25,400 sales, it ranked first in the sales list of SUVs with a price of more than 300,000 yuan in the Chinese market, and the sales of EV with a price of more than 200,000 yuan ranked top three in the list. (Data from Li Auto)

▲ Li L9 the 10,000th production car rolled off the production line

It is understood that the current peak capacity of the Li Auto is 7,500 units/week, and Q4 will sprint to 10,000 units per week. It can be said that, whether from the sales or production point of view, in the field of EV industry, Li Auto has shown its strong momentum of development.

If a worker wants to do a good job, he must first sharpen his tools. The stability of the equipment is an important condition to ensure production capacity, and it is also a weapon to ensure that Li Auto occupies the market. In 2021, in line with their respective advantages, so that green/energy-saving/high-tech EV products benefit more consumers, Li Auto and Tederic successfully hand in hand.

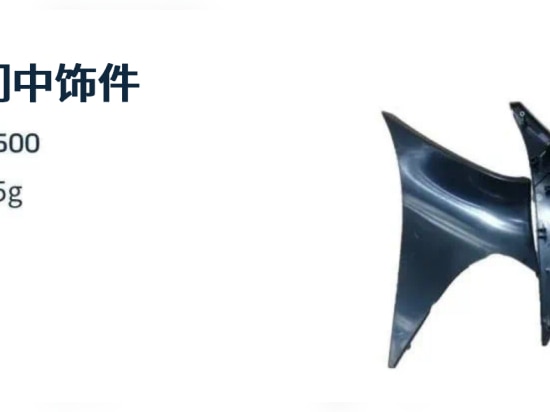

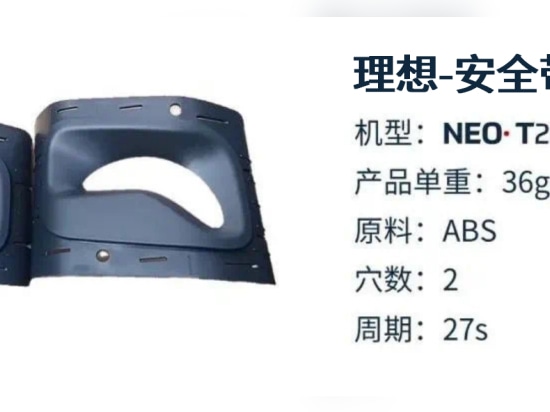

At present, Tederic has a number of NEO·M series Multi-Component Injection Molding Machine with Vertical Rotary Turntable and NEO·T Toggle System Injection Molding Machine serving the injection molding production of Li Auto’s automotive headlights and interior parts.

How does Tederic help users core "out of the loop"?

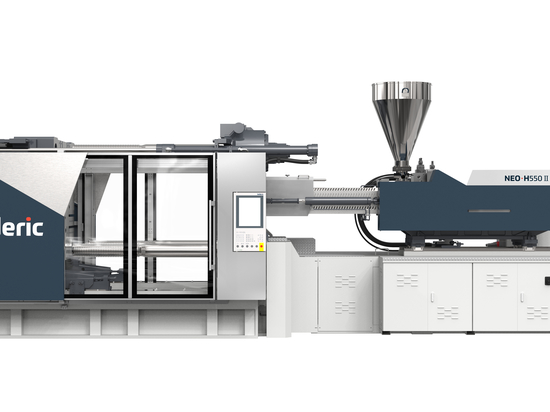

The NEO·M series large multi-material injection molding machine runs smoothly and is equipped with SpinSure®V - vertical turntable technology, which allows the turntable servo control accuracy up to 0.01°, making it easy to handle high-quality injection molding of headlights. The modular shooting platform structure is freely arranged and flexibly forms more than 30 combinations to meet the possibility of a variety of colors for a machine and provide diversified solutions for users.

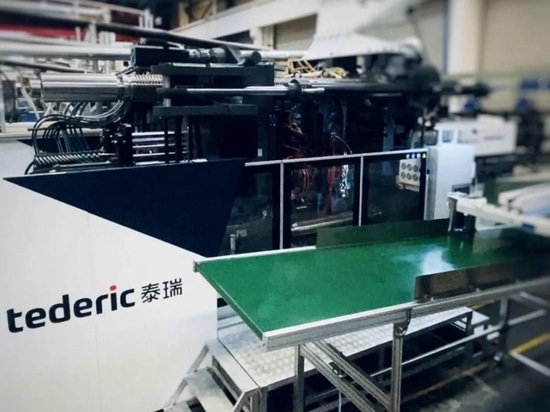

▲ Tederic injection molding machine in customer production base

Compared with the traditional hydraulic system, NEO·T series elbow injection molding machine saves 30%~80% of energy. The new generation servo power system is ultra-high response, 28ms can reach the highest pressure, and can run continuously for more than 10min at full pressure and full speed, which can effectively shorten the injection molding cycle of automotive interior parts and improve production efficiency. The repeating accuracy of the opening and closing mold is within ±1mm, and the repeating accuracy of the interior decoration products is within 0.3%.

▲ Tederic injection molding machine in customer production base

As one of the earliest injection molding machine enterprises in the field of EV in China, Tederic focuses on product research and development and process innovation, and converts accumulated years of technical advantages into product advantages, and its NEO series injection molding machine has been recognized and praised by the majority of users with its precision, flexible and stable characteristics.

At present, Tederic fully supports many kinds of intelligent injection molding solutions such as EV headlight vision system, automotive interior and exterior trim, such as headlight masks, through-line taillights, and automotive front door trim.

Strong independent casting, precision machining strength and complete industrial chain make Tederic different. Under the integration of the whole industry chain resources, Tederic is rising as a new force of intelligent injection molding turnkey solutions for EV industry, and looks forward to joining hands with more users around the world in the future!