#Industry News

Tederic tailors interior solutions for global auto leaders

As the popularity of the four injection molding machines of Tederic NEO series continues to increase worldwide. In Germany, from Isar to the North Sea, more and more plastics processors are using economically attractive and reliable injection molding

NBHX Trim Group is a leading global supplier of innovative surfaces for high-quality automotive interiors with its European headquarters in Bruchsal, Germany.

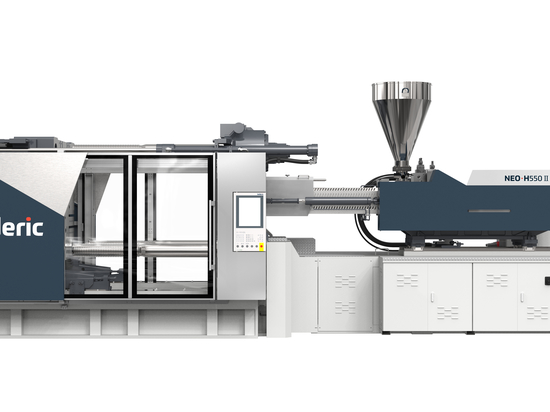

Four months ago, the user reached a strategic cooperation with Tederic for injection molding solutions for automotive interior parts, and purchased a number of second-generation NEO·H two-plate injection molding machines. These machines have been put into the user's production site in Romania, mainly for the production of high-end automotive brand interior parts.

01Core technology to achieve customized solutions

Over the years, Tederic has actively practiced the concept of "Smart Injection", and with the continuous breakthrough of independent innovation technology, a number of core injection molding processes have gained more and more attention in the global market. In this cooperation with users, Tederic provides a customized solution with free programming for core withdrawal around the second generation NEO·H two-plate injection molding machine to meet the complex molding requirements of automotive interior parts.

For automotive interior manufacturers, a precise and stable production process is a top priority. According to the needs of users, Tederic uses the process technology independently developed and obtained the "international leading" appraisal to break through the bottleneck of traditional injection molding process and effectively improve the sensory quality of automotive interior injection molding parts.

In addition, the precision template parallelism control, while ensuring the perfect dimensional accuracy of the product, but also reduce the mold loss and injection molding machine energy consumption, reduce the user's plastic processing costs.

02Fruitful cooperation between China and Germany

In the face of the diversified needs of global automobile manufacturers in injection molding production, Tederic accurately analyzes the development trend of the industry, and constantly introduces forward-looking and innovative new products, new technologies and new applications in the field of injection molding, providing important support for the innovative development of the global automotive injection molding industry chain.

The international cooperation between Tederic's German R&D center and China headquarters convinced customers. Christian von der Linde, Chief Financial Officer of NBHX Trim Group, said that he is very excited about the injection molding solution of automotive interior parts under Tederic's international cooperation and is excited about the initial results of Tederic's new machine.

In the face of the development trend of the new energy automobile industry, Tederic has reached close cooperation with a number of international auto parts manufacturers, and applied the whole industrial chain intelligent manufacturing to all stages of intelligent injection molding solutions.

It is worth mentioning that since its establishment, Tederic has launched the overseas market layout. In the process of development from point to point, the formation of four overseas subsidiaries in Portugal, South Korea, Mexico, Brazil, the first stage of the layout structure, the global service network to maximize the degree of overseas users to meet the complex injection molding solutions and overseas layout production needs.

In the market of user experience first, timely insight into the needs and meeting the needs has become the key to winning. Tederic can stand out among many competitors, not only the embodiment of Tederic's technological innovation strength, but also the concentrated display of Tederic's recognition and trust.