#Industry News

Leading the way, Tederic's innovative injection molding solutions enable lightweight vehicles

With the continuous upgrading of new energy and intelligent connected vehicles, reducing the quality of vehicle maintenance through material, structure and process lightweight has become the trend of the world's automotive development.

For the new energy auto parts manufacturing industry, the vehicle weight as one of the important factors restricting the development of EV, how to effectively reduce the weight to reduce energy consumption, while breaking through the high efficiency injection molding production limits has become the most core proposition.

01The popularity of high-profile products continues

As the star exhibit of Chinaplas 2023, the OptiSure™ multi-layer thick wall lens injection molding solution brought by Tederic's new NEO·Hb rotary mold core injection molding machine was well received during the exhibition period.

Focusing on technological change and product innovation, Tederic took the lead in becoming a domestic plastic machine enterprise with rotary mold core technology. After the exhibition, star products continue to be welcomed.

Not long ago, based on the advantages and convenience of Tederic's global marketing service network, Tederic's products have gained the favor of multinational auto parts manufacturers, and customers are convinced by Tederic's products, technologies and intelligent injection molding solutions.

02Innovative solutions for weight reduction and productivity

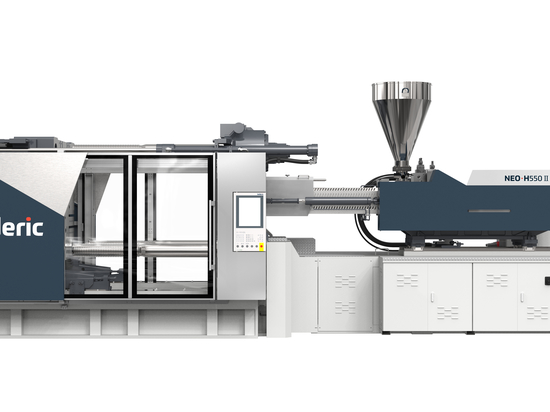

The customer is a leading global supplier of automotive exterior parts, with production requirements for automotive triangle Windows. In the first collaboration, Tederic broke through the traditional semi-automatic wrapping method. NEO·H680IIb rotary mold core injection molding machine as the main body, the use of more lightweight, strong design, toughness higher transparent PC material instead of glass, through the rotary shaft two-color automatic wrapping, to achieve the original application mode of innovation and upgrade.

Compared with the traditional glass triangle window, the weight reduction effect of PC material is immediate. The innovative application of this technology is to rotate the preformed PC as the first component into another cavity, leaving a space for encapsulation, so that the second component is fed from behind the first component.

The innovative process enables multiple injection molding and fully automatic edging, which not only reduces weight, but also improves the efficiency of the user's vehicle production final assembly line. The scheme is industry-leading and greatly improves the production efficiency and yield of the user's triangular window processing.

In addition to the triangular window, the rotary mold core technology is also suitable for special products such as thick wall lenses, which solves the technical problems that ordinary injection molding cannot produce efficiently and accurately.

03Lead the new trend of injection molding production of automotive exterior parts

Tederic's innovative injection molding edge solution not only reduces the weight of the vehicle, reduces fuel consumption, saves the cost of the vehicle, but also increases the safety and driving performance of the vehicle.

We have reason to believe that this innovative program will be promising in the future lightweight design of new energy vehicles, and will become a new trend and new direction of the production of automotive exterior molding process.

As a leading provider of intelligent injection molding solutions, Tederic actively seeks to diversify its development. With the achievements of independent innovation continue to make new breakthroughs, products are getting more and more attention in the global market.

As the user said: "Tederic is well known internationally and innovative technologies and processes meet our production needs. We look forward to this injection molding program for automotive exterior parts, and look forward to further international cooperation with Tederic in the future."

With a deep understanding of global users and forward-looking insights into the market, Tederic continues to introduce products with flexible, innovative and intelligent trends.

We look forward to working with more international users to create value, in product innovation and production layout, and constantly improve the product and service system for the international market. Accelerate the intelligent development of the auto parts industry and enable a beautiful travel experience.