#Trade Shows & Events

Tederic appeared at the Plastics & Rubber Indonesia2023

On November 15, local time, Plastics & Rubber Indonesia IA2023 was held in Jakarta International Convention and Exhibition Center, Indonesia.

As Southeast Asia's top plastic, rubber, mold comprehensive exhibition. The exhibition scale of more than 40,000 square meters, a total of 31 countries/regions exhibitors appeared on the same stage.

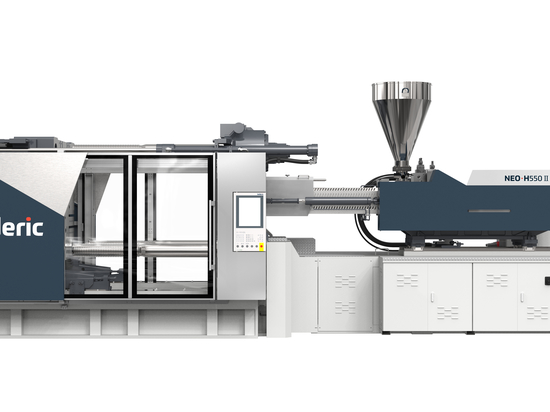

During the exhibition, Tederic brought two elbow injection molding machines to the exhibition site. The NEO·T500 and NEO·T260 represent one-stop smart injection molding solutions for the automotive and packaging industries, respectively.

The theme of this year's exhibition is "The future of plastics", and Tederic is here to answer the theme. Fully demonstrate the strong strength of Tederic injection molding leading, trend leading and product leading.

In the reception area of the booth, Tederic business partners conducted in-depth exchanges and discussions with the on-site audience and established contacts with many potential customers.

01 Auto fender intelligent injection molding solution

Precise pulse, targeted measures. In view of the current automotive plastic parts as one of the important roles in vehicle production. Based on its rich experience in the field of automotive injection molding, Tederic further promotes the development of automotive parts to high-quality injection molding.

NEO·T500 adopts advanced injection double-layer wire gauge structure to meet the production of large thin-wall auto parts, with smooth and smooth surface and uniform wall thickness after molding.

Tederic is committed to continuously deepening the integrity of one-stop intelligent injection molding solutions through technology-enabled products, providing customized solutions for users in the automotive industry.

The quality repetition accuracy of the automobile fender produced by this scheme is less than 0.5%, which not only meets the high-quality molding of high-end precision parts, but also can easily adapt to the production requirements of multi-cavity large-capacity molds. Using a new generation of servo power system, compared with the traditional hydraulic system, energy saving 30%~80%, taking into account the economy and efficiency of automobile fender production.

The audience responded: "Different from other exhibitors showing daily or packaging products, Tederic's car fender injection molding demonstration scheme is special." It is not difficult to see that the car fender scheme highlights Tederic's professionalism in the field of automotive parts segmentation and the perfect forming effect of complex products.

02 Smart injection molding solution for bottle caps

During the exhibition, Tederic booth NEO·T260 attracted the appreciation experience of on-site guests with cutting-edge injection molding technology, fully demonstrating the strong influence of Tederic molding machine leaders.

Tedericcontinuously optimizes the performance and cost efficiency of its products, making its bottle cap smart filling solutions a leader in the market in terms of cost performance. The scheme is easy to operate, cost-effective, and helps users to maximize benefits.

In addition, strict control of mold injection molding, temperature and pressure control and other links, the bottle cap is beautiful and high quality, and fits the needs of high-speed and efficient production of customers in the packaging market.

This time to Indonesia, Tederic face to face to understand the needs of local users. In the face of new market demand and changes in the development pattern of the industry, Tederic will continue to lead the development of the industry, take the user as the center, realize the innovation leap in China's injection molding field, and create more value for global users.