#Industry News

For Hongqi car to add innovation and productivity, Tederic has been deeply recognized by auto parts customer

"A large machine for the production of automotive precision injection moulded parts"

This is a concise summary from the head auto parts manufacturer - MINTH Group after purchasing the first Tederic DH1900 IMM.

In the past two decades, MINTH Group has been producing auto parts such as grille assembly and triangle exterior plate for Great Wall Motor, FAW Toyota, Dongfeng Nissan and FAW Volkswagen.

Since 2020, customers have been exposed to a wide range of Tederic machines in different series and sizes, and have finally been impressed by Tederic's large tonnage multi-material injection molding machines.

01Trust in the Tederic brand

Since the establishment of Tederic, with the further expansion of the brand's influence in the international market, it has attracted the attention of many auto parts manufacturers.

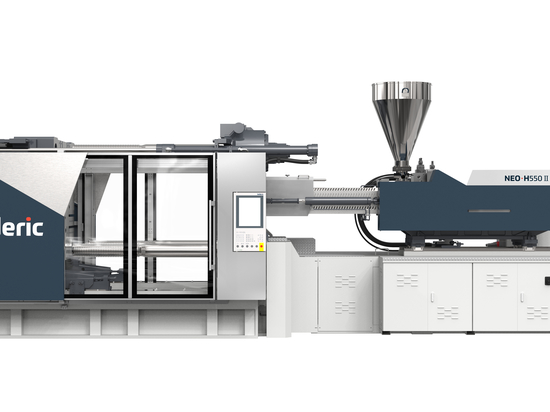

The customer quickly noticed the NEO series multi-material injection molding machine, and they had accumulated a lot of experience in the traditional products of Tederic, and the product yield and production efficiency have achieved excellent performance.

In addition, Tederic's all-round user care and after-sales service experience are also very good, timely understanding of needs and rapid feedback left a deep impression on customers.

Soon after, the customer "firmly and confidently chose Tederic again." Purchase a number of NEO·M1120s shooting machine, high quality interpretation of domestic automobile brand representative - Hongqi car B-pillar cover injection solution.

02Deep recognition of NEO·Ms

Since 2022, a number of multi-material injection molding machines with a clamping force of 11200kN have acted as the main force equipment for the injection molding production of customers' auto parts.

The NEO·M1120s horizontal rotary multi-component injection molding machine uses a 2-cavity mold to produce the B-pillar decorative cover plate of Hongqi car. The Tederic CoinSure™ injection molding process provides high precision, high quality product molding for exterior parts, which are removed and placed on the conveyor belt by the YASKAWA robot for testing.

According to customers, the product rate of the equipment has reached as high as 96%.

At present, customers have applied Tederic one-stop injection molding solutions more widely, and have launched in-depth cooperation with Tederic to explore innovative injection molding solutions for automotive exterior parts.

In September 2023, the customer again ordered several Tederic NEO·M1320s. Continue to increase innovation and productivity, to provide intelligent injection molding solutions for exterior parts for the global new energy automobile giant - BYD.

As the client said at the time of the re-purchase: "We have previously worked successfully with Tederic on a number of projects. This time, we firmly and confidently join hands with Tederic again to create an industry benchmark!"

03Deep cooperation and joint innovation

Stable and reliable products, technologies and services, so that Tederic one-stop intelligent solutions can see the real visible high return. This is an important reason for Tederic to win customer trust and reputation, prompting customers to continue to re-purchase and continue to increase.

In the three aspects of injection molding accuracy, performance and stability, Tederic injection machine innovates the design of heating, injection and mold units, develops multi-color, large-tonnage, multi-injection molding equipment, greatly improves the application experience, and helps the efficient and stable production of key components in the field of EV.

The combination of innovation and productivity is the main tone of the Tederic solution. At present, a number of industry giants are deeply cooperating with Tederic to jointly explore innovative solutions and innovative technologies in the automotive field.

In the face of repeated changes in the automotive industry, based on those new topics coming forward, Tederic looks forward to working with more customers to carry out new exploration and innovation together, and meet the opportunities contained in every challenge.