#Industry News

Come for needs,Tederic IKON die casting machine successfully released

On January 9, the launch ceremony of Tederic IKON large-scale three-plate direct pressure die-casting machine was held at Tederic's global headquarters.

At the event site, supporting enterprises in the upstream and downstream industry chain of die casting industry, well-known experts in the field of die casting, senior leaders of Tederic, overseas guests of Tederic, and team members of Tederic Die casting Machine Division attended the launch ceremony with media friends to witness the launch of Tederic IKON three-plate direct pressure large-scale die casting machine. To commemorate the milestone day of Tederic's entry into the field of integrated molding high-end equipment.

The press conference ceremony was a complete success and triggered a strong response inside and outside the industry.

01

It's a vision and a belief

Tederic aspires to be a global leader in molding equipment and solutions

As night falls, Tederic's global headquarters building glows in the dark. Dormant for nearly two years, the Tederic IKON450 die casting machine located in the factory is about to be awakened.

At the press conference, Zheng Jianguo, chairman of Tederic Machine Co., LTD., accurately summarized the original intention and vision of Tederic's entry into the integrated die casting field with "the right time, the right place and the right people". In the face of the current demand trend of the automotive industry for large and ultra-large integrated die-casting islands, the Chinese solution of new energy vehicle manufacturing is constantly refreshing the new height of intelligent equipment. Tederic has been deeply engaged in molding equipment for 20 years, and has a deep understanding of the key technologies and capital strength of large-scale molding equipment, and has enough capacity to carry the fast and stable die-casting machine projects. In the future, IKON will bring a double breakthrough of responsibility and value to the progress of the die casting industry.

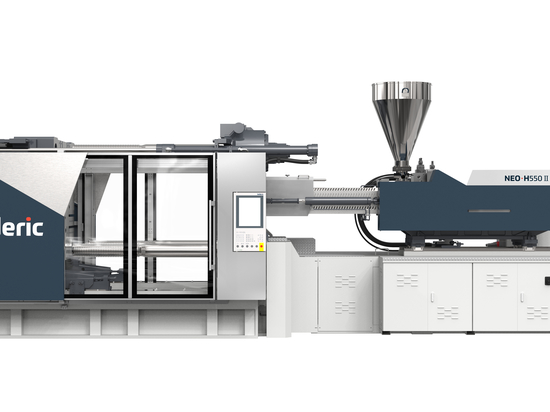

At the press conference, Zhang Hongpeng, general manager of Tederic Die Casting Machine Division, shared the strategic planning and product introduction of Tederic IKON die casting machine. He mentioned, "Over the past two years, Tederic has concentrated on research and development by researching industry needs, determining product positioning, integrating European die casting machine technology, talent and resources. In view of the requirements of ultra-large structural parts and customer pain points, in-depth research has been carried out in the design and development of ultra-large structural parts, heat-treat-free materials, ultra-large mold design and process development, ultra-large die casting machine design, manufacturing, and the overall integration of intelligent ultra-large die casting units. At present, IKON's full range of die-casting machines of 1,400 to 9,200 tons has been developed, and mass production will be brought to the market in 2024."

IKON series of large die-casting machines focus on the field of automotive structural parts, led by Tederic Munich R & D center research and development, performance against the European system. IKON series of large die-casting machines break through the traditional design concept of the industry and will bring value beyond the expectations of customers in the automotive industry.

Zhang Hongpeng said, "After 20 years of development, Tederic has become A benchmark for the automotive industry and European brands in the plastic molding equipment industry, and is currently the only A-share main board listed enterprise in the industry." On the occasion of Tederic's 20th anniversary, we launched the die casting machine project as the second growth curve of Tederic's future rapid development. In addition, Tederic's many years of experience in R&D, manufacturing and delivery of high-end equipment for overseas markets, as well as its strategic experience in the standard European system and focusing on the molding of high-end automotive parts, have greatly helped our die-casting machine project.

In the future, Tederic will create greater value for customers in the automotive industry with a variety of molding equipment and solutions such as plastic molding and metal molding, so that customers can obtain competitive auto parts production capacity and obtain better return on investment."

02

Black technology strong empowerment

Excellent technology creates a new era of integrated die casting

At present, in the field of automotive die casting, the quality of structural parts accounts for 20-30% of the quality of automotive maintenance, which is the key area of integrated die casting lightweight. Due to the large size of the product, the long filling stroke, the large difference in thickness and the relatively dispersed important position, the structural parts have become one of the more difficult categories in the field of auto parts die casting production, but for the processing equipment for the production of structural parts, the imported die casting machine equipment has occupied the majority of the market.

Zhang Hongpeng, general manager of Tederic Die Casting Machine Division, said: "As a latecomer in the die casting machine industry, we want to challenge high-difficulty molding products. Based on Tederic's native international technical advantages, the IKON450 will focus on the production of automotive structural parts. Equipped with SNP real-time control injection system and three-plate direct pressing die closing system, with excellent performance, extreme stability and reliability, it will redefine the large cold chamber die casting machine, realize domestic replacement of imports, and deduce the classic integrated high-end metal forming equipment.

There is something inside, and the appearance is the highlight.

At the press conference, Zhang Hongpeng announced the core highlight of IKON - SNP real-time control injection system.

The system is equipped with a custom-developed 10,000Hz scan frequency controller, SmartCast casting process system, fifth-order PID algorithm, MCK large model self-learning algorithm, BLC oil circuit system, custom-developed high-response servo valve and high-performance check valve. SNP real-time control injection system, with more than 40% of the conventional dynamic injection force, more than 70G ultra-high acceleration, speed, pressure, position repetition accuracy than the traditional die casting machine has been greatly improved. At present, IKON three-plate direct pressure clamping system has obtained Chinese invention patent.

In addition, the clamping force of IKON clamping system is evenly distributed, and the deviation of clamping force of Corinth column is less than 3%. Inorganic hinge structure, close to lifelong maintenance free, with automatic clamping force compensation function, combined with special formula template material, the service life of the clamping mechanism is longer.

Overall, IKON series of large die-casting machines, with no porosity injection, no flash molding, stable, durable advantages, is an excellent structural parts forming solution. In the field of ultra-large structural parts, Tederic has the overall turnkey solution capability to meet the design and manufacturing of ultra-large integrated structural parts for new energy vehicles.

At the press conference, By Tederic machine chairman Zheng Jianguo, Tederic machine die casting machine division general manager Zhang Hongpeng, China Foundry Association executive Vice president Gao Wei, China Foundry Association die casting branch full-time deputy Secretary-General Qian Ming, Guangdong Hongtu director Song Xuanpeng, Suzhou Adlin Chairman Shen Lingen, Nanfeng Auto Parts chairman Lu Rencong, Huafeng Power chairman Zhang Qinyong, Runxingtai chairman Zhang Ying, FAW Casting you Chief engineer Tong Guodong, Professor Zhao Peng from Zhejiang University, Professor Xiong Shoumei from Tsinghua University and Professor Peng Liming from Shanghai Jiao Tong University jointly unveiled the exhibition.

With the big screen slowly moving, the audience at the conference witnessed the birth of this subversive die casting machine IKON450, which brought a new milestone for automotive metal forming manufacturing.

03

Strategic cooperation to force the integration of automotive parts die casting circuit

Tederic's first IKON successfully delivered

After the shock appearance of Tederic IKON450, the conference site ushered in a moment to work together to create the future. Taicang Nanfeng Auto Parts Co., LTD., Yingkou Huafeng Power Development Co., LTD., Zhuhai Runxingtai Electric Co., LTD., Guangdong Hongtu Technology Co., Ltd. signed strategic cooperation agreements with Tederic respectively. Among them, this strategic signing covers the cooperation of more than 9,000 tons of super-large die-casting islands.

In the field of die casting, Tederic looks forward to working with strategic partners as a long-term solid force for each other to jointly develop the die casting circuit of automotive precision parts.

Signing ceremony of strategic cooperation agreement

At this launch ceremony, Tederic achieved the first IKON delivery ceremony. After two years of painstaking research and development and polishing products, the first IKON 450 has been completed in August 2023 commissioning, through the structural parts of the strict test and small batch production, performance and stability to meet the design objectives and requirements.

At the conference site, Zhang Hongpeng, general manager of Tederic Die-casting Machine Division, symbolizing the key of innovation and win-win cooperation, was successfully delivered to Shen Lingen, chairman of Suzhou Yadlin Co., LTD., opening the door of future manufacturing for Yadlin precision automotive metal forming.

As the first user of Tederic IKON large die-casting machine, Shen Lingen, chairman of Suzhou Yadlin Co., Ltd. expressed his views on IKON. He believes: "As a rising star, Tederic IKON series three-plate direct pressure large die-casting machine has dared to challenge and successfully broken through the core technology of structural parts molding, providing solutions for the global production of structural parts, which is a good thing for customers and the industry."

04

To create a benchmark

Tederic integrated molding high-end equipment base to meet the full range of die casting machine manufacturing below 20,000 tons

It is worth mentioning that this launch ceremony links the two major production bases to visit, experience the advantages of Tederic's independent industry chain integration, and feel the competitive production and manufacturing strength of high-precision castings.

Among them, Tederic global headquarters building in accordance with the 4.0 factory construction, to create the global injection molding industry optimization process, advanced technology, highly automated intelligent degree of "future factory", fully reflects Tederic green, intelligent concept. In the future, Tederic headquarters and the all-electric intelligent production line will achieve an annual production capacity of more than 3,000 electric injection molding machines, and will also become a new landmark in Qiantang District, Hangzhou.

On the other hand, Tongxiang integrated molding high-end equipment base is currently in hot preparation. The base is equipped with international processing equipment to meet the manufacturing of a full range of die casting machines under 20,000 tons, not only to provide customers with better products, faster delivery, but also to provide customers with a full range of services such as mold testing and training.

We have reason to believe that with strong manufacturing strength, Tederic IKON will become a new benchmark in the global molding industry, providing users with efficient, complete and sustainable industry-wide die casting molding solutions!

On this momentous day, Tederic invited the attendees to a gala dinner. At this point, Tederic's "IKON Die-casting Machine Launch Ceremony" was successfully held!

Tederic stands on the legacy of past innovations, starting from zero and going from zero to one. This launch ceremony is not only the global debut of Tederic IKON, but also an important milestone for Tederic to become a global leader in forming equipment and solutions, which means that Tederic will further focus on the automotive industry, around plastic forming equipment and metal forming equipment, to help the development of the global automotive industry and win the international stage!