#Industry News

Dialogue first IKON user Yadelin: IKON is worthy of trust

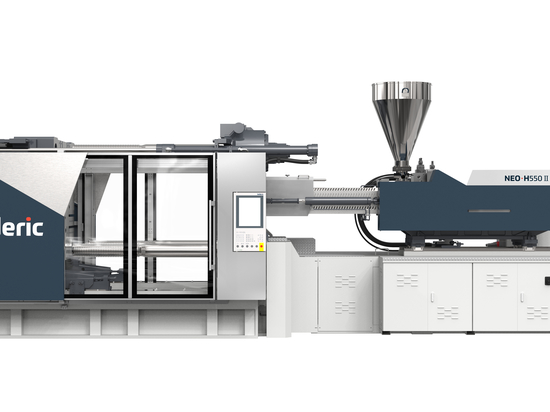

With the successful launch ceremony of Tederic IKON three-plate direct pressure large die-casting machine, Tederic has received strong attention from the industry.

Tederic has been deeply engaged in molding equipment for 20 years, and has a deep understanding of the key technologies of large-scale molding equipment. Based on years of experience in R&D, manufacturing and delivery of high-end equipment for overseas markets, as well as strategic experience in targeting Europe and focusing on the molding of high-end automotive parts. IKON series of large-scale die-casting machines break through the traditional design concept of the industry, focusing on the field of automotive structural parts, and the performance is fully benchmarking Europe.

As Tederic's first IKON user, Shen Lingen, chairman of Suzhou Yadelin Co., Ltd. expressed his views on the current automotive structural parts production equipment. He believes: "As a manufacturer of structural parts, in the past, for the molding of structural parts, we have chosen imported die casting machine brands as production equipment. But imported die casting machine brand price and maintenance costs are relatively high, so we have been looking for a domestic die casting machine that can replace imported brands."

In fact, as the Chinese program of EV manufacturing is constantly refreshing the new height of intelligent equipment, the wave of domestic substitution is accelerating. As a high-tech enterprise engaged in the research and development, production and sales of aluminum alloy and aluminum alloy precision parts, in the face of the domestic substitution trend, Yadelin actively opens the "acceleration" through the product, technology and production layout, impacting the global automotive precision metal parts innovation highland.

"In May last year, I was impressed by the design concept of Tederic IKON series large-scale die-casting machine and the solution of structural parts. In September, we tried out several structural parts products for us, and the effect reached our expectations, so we are assured to be the first user of IKON."

It is understood that the first IKON 450 has completed commissioning in August 2023, and has passed the strict mold test and small batch production of structural parts, and the performance and stability have reached the design goals and requirements.

As Shen Lingen, chairman of Suzhou Yadelin Co., LTD.,said, "Tederic IKON series large-scale die-casting machines, as a rising star, dare to challenge and successfully break through the core technology of structural parts molding, providing solutions for the global production of structural parts, both for customers and the industry is a good thing."

As a large die-casting machine developed by Tederic Munich R&D Center, IKON is equipped with SNP real-time control injection system, which has a dynamic injection force exceeding 40% of the conventional, ultra-high acceleration exceeding 70G, and the speed, pressure and position repetition accuracy are greatly improved compared with the traditional die-casting machine. IKON provides excellent solutions for the forming of precision automotive structures.

All along, Tederic has been speaking with innovative technological achievements, creating market pioneers again and again. We believe that IKON large-scale die casting machine will open a more competitive return on investment for precision automotive metal molding of Suzhou Yadelin Co., LTD., and will also inject strong new impetus into the innovation and development of China's die casting industry.