#Trade Shows & Events

Tederic NEO·H500b Rotary mold Core Multi-layer Injection Molding Machine won the "2024 Ringier Technology Innovation Award"

On March 13, Tederic NEO·H500b Rotary core multi-layer injection molding Machine won the 2024 Ringier Award for Technological Innovation. This honor is organized by Ringier and selected by a panel of authoritative experts.

On March 13, Tederic NEO·H500b Rotary core multi-layer injection molding Machine won the 2024 Ringier Award for Technological Innovation. This honor is organized by Ringier and selected by a panel of authoritative experts.

Since winning the Technology Innovation Award for the first time in 2010, Tederic has continued to enable high-quality development of enterprises with scientific and technological innovation, and has continuously demonstrated its technological breakthroughs and excellent performance on the automotive injection molding circuit.

Product Manager NEO·H, Product Center, Tederic Injection Molding Machine Division

Zeng Jianqin attended the award ceremony and delivered an acceptance speech

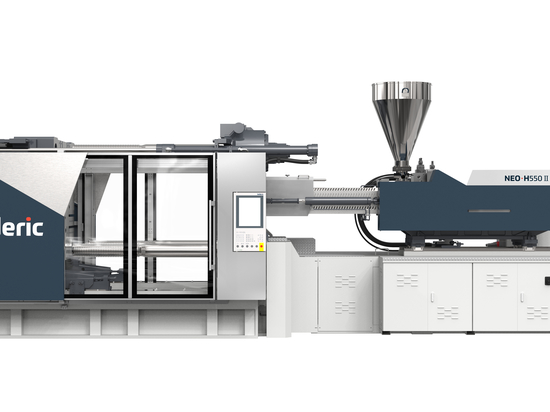

NEO·H500b rotary mold core multi-layer injection molding machine has developed a modular precision rotary mold core mechanism to realize the combination application of electric Angle type double injection table and two-plate lock mode injection molding machine, and the product design flexibility is significantly improved.

For an automotive headlamp lens with a typical thickness of 30mm, it usually takes 10-15 minutes to complete a mold production with a standard injection molding process.

As a model of injection molding solutions for EV optical parts, NEO·H500b rotary mold core multi-layer injection molding machine innovates the development of rotating shaft multi-station precision rotation control system to achieve multi-layer lens injection molding, replacing 800 seconds of traditional lens injection molding production time with 200 seconds, increasing the production speed by 30%, and achieving a major breakthrough in the injection molding efficiency of automotive optical lens products.

Based on the high level and high performance of the product, the NEO·H500b rotary mold core multi-layer injection molding machine successfully passed the Zhejiang Provincial industrial new product identification in 2023. Related technologies have authorized 1 invention patent and 1 utility model patent, which will promote and drive the high-quality development of the plastic machine industry in the future.

Tederic has been committed to creating greater value for users, through continuous innovation of products and optimization of service models, to provide users with more convenient and flexible one-stop intelligent injection molding services to meet the needs of diverse industry applications.

At present, Tederic's solutions and successful practical experience in the automotive industry are helping EV auto parts manufacturing enterprises to achieve safe, efficient, green and innovative transformation and upgrading. Looking forward to the future, we look forward to the continued deep integration of innovative products and injection molding technology, laying a road to innovation for the transformation and upgrading of global EV.