#Product Trends

Tederic and Galaxy Geely Lead the Way in Interior Aesthetics

Entering the era of smart cars, the interior space is gradually becoming the third largest living space for people in addition to home and office, and the design of car interiors has also become a key factor affecting the in-vehicle experience.

Entering the era of smart cars, the interior space is gradually becoming the third largest living space for people in addition to home and office, and the design of car interiors has also become a key factor affecting the in-vehicle experience.

Relevant data shows that with the transformation and upgrading of the new energy vehicle industry, sales of electric hybrid SUVs and sedans in China's auto market surged 80% in the first five months of this year. As one of the high-value brands favored by users in the mainstream new-energy market, Geely's Galaxy L7 has been performing particularly well in recent sales, and is highly popular among consumers.

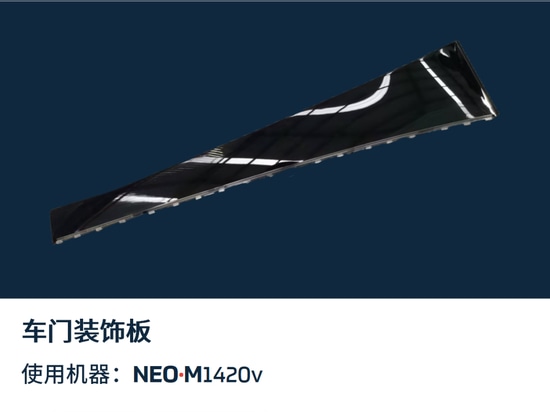

The perfect blend of technological functionality and comfort in the interior components is the key for consumers to perceive the overall quality of the car. Throughout the interior design of Galaxy L7, it adheres to the concept of modern aesthetics and incorporates the wisdom of technology and humanity.

Tederic’s interior component solutions, new trend in aesthetics

Behind the exquisite craftsmanship of the interior, it cannot be separated from the strong support of injection molding processing equipment.

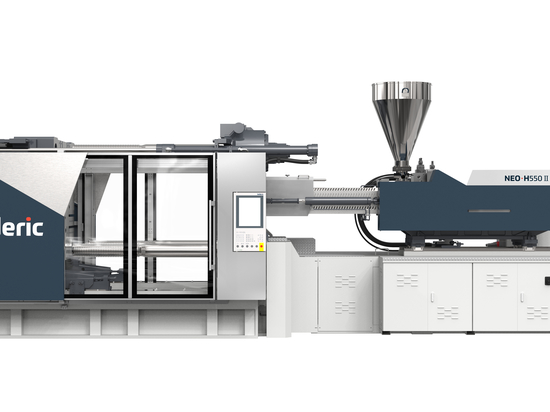

As the main processing equipment for Galaxy L7 door trim panels, Tederic's NEO-Mv series vertical rotary multi-component injection molding machine operates smoothly, and with SpinSure®V - independent rotary technology, the rotary servo control accuracy is up to 0.01°, which meets the high efficiency and high quality of injection molding production of interior trim parts.In addition, the solution adopts multiple innovative injection technology to provide customized solutions for the individual production needs of automotive interiors.

Solution highlights:

Flexibility: With MultiMold™ technology, the modular injection molding table structure can be flexibly formed into more than 30 kinds of assembly methods to meet the diversified production needs of automotive interiors;

High efficiency: Diagonally balanced distribution of fast mold transfer cylinders, faster opening and closing speed, effectively shorten the cycle time, help users quickly respond to market demand;

High quality: with GlosSure™ high-gloss treatment technology, the surface finish of plastic products is high, the visual effect is more exquisite, and the overall yield rate of high-gloss interior parts is high;

Precision: the injection unit and mold clamping unit are tightly integrated for high production stability;

Intelligent: freely programmable to provide customers with customized requirements, more stable mold temperature control.

Advanced injection molding technology and excellent design concepts not only enhance product quality, but also bring consumers a higher quality driving experience.

To date, many NEO-M series multi-material solutions have been applied in Geely Automobile to meet the application scenarios of new energy automotive lamp vision system and automotive interior and exterior parts.

Nowadays, "human-vehicle-home ecosystem" has become an important part of future intelligent life.

Facing the market demand for high efficiency and high quality production in the automotive industry, Tederic has launched many customized solutions for the automotive industry based on its independent core injection moulding technology, and continued to plough into research and development of products and process innovation in the field of new energy automobiles.

We look forward to working with more users to create a more comfortable and personalised interior, and together create a new era of new energy vehicle interior aesthetics.