#Industry News

Tederic GIGA : Officially Completed and Put into Operation

July 26, Zhejiang Tederic Equipment Co., Ltd. large integrated intelligent manufacturing base (annual output of 5,000 units of injection molding high-end equipment construction project, hereinafter referred to as the GIGA plant) completion of the commissioning ceremony was successfully held in Tongxiang City, Zhejiang Province.

Yu Huiyou, Wang Jian, Pan Chuandi, Chen Lingen and other four sets of leaders, municipal leaders of various departments, development distract, towns (streets), the main person in charge, the chairman of the board of directors of the Tederic Machinery Company Limited, Mr. Zheng Jianguo, and the senior management of the Tederic Machinery Company Limited gathered at the site of the ceremony, the scene announced that the GIGA plant was officially completed and put into operation!

01. 247 Acres:Tederic's largest integrated production base

Since the groundbreaking on 18th October 2022, the GIGA plant has attracted a lot of attention and expectation from all walks of life. As a benchmark project for Tederic's entry into the field of integrated forming and high-end equipment, the GIGA plant covers an area of 247 acres and has become the largest integrated production base in the world.

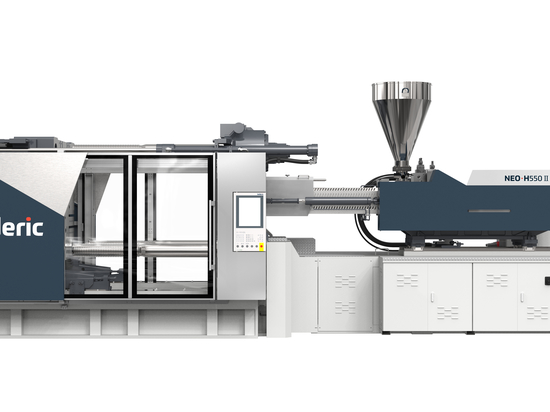

The plant has been built into an efficient and intelligent integrated moulding equipment industrial base, undertaking the processing of castings and steel parts, the assembly of electro-hydraulic machines and the production of integrated large-scale high-end equipment for the Tederic Group. Providing customers from New energy vehicles and other industries with plastic moulding, metal forming and other multi-faceted integrated moulding solutions.

Production workshops are equipped with flexible production lines, high-precision machining equipment group, load-bearing 300-tonne floor boring machine and gantry several, load 300-tonne travelling crane several, heat treatment lines and other supporting equipment nearly the whole industry chain. In addition, equipped with large, medium and small-sized machine assembly pulsating line, which improves assembly efficiency and shortens assembly cycle to provide customers with high quality and fast delivery.

Overall, the GIGA plant can meet the manufacture of injection moulding machines up to 4500 tonnes and a full range of die casting machines up to 20000 tonnes, which not only provides customers with better products and faster delivery, but also provides customers with a full range of services such as mould trial and training.

02. Model Plant, 0-carbon Future

The GIGA plant further highlights Tederic's efforts in practicing sustainable development.

It is reported that the GIGA plant has the industry's top-scaled single-unit production workshop, which is one of the best masterpieces of Tederic's practice of green development. 11.69MW of photovoltaic power generation is adopted on the roof of the factory, which can realise an average annual power generation capacity of 11,422,300kWh, which is equivalent to the annual consumption of 4,000 ordinary households. Not only does the factory achieve self-supply of internal energy, but also 37% of the remaining surplus electricity can be connected to the grid, making it a true ‘0-carbon’ factory of the future.

In addition, it can save about 3805 tonnes of standard coal per year, while reducing the emission of many air pollutants. Among them, about 9,515 tonnes of carbon dioxide will be reduced, and about 4.7 tonnes of dust will be reduced, which is a significant benefit in terms of cost reduction and efficiency, resource saving and environmental protection.

‘This is an exciting starting point. The completion of this base is a symbol and milestone for Tederic's entry into the field of integrated moulding high-end equipment. Strictly following the principle of co-development of ecological environment and high quality, Tederic's GIGA plant has now become our largest integrated production base in the world, and will set an example of sustainable production in China and the world.’ said Zheng Jianguo, Chairman of the Board of Directors of Tederic Machine Co.

The factory is just a microcosm. Nowadays, Tederic strongly supports the development of green and low-carbon industrial chain, and is committed to become the advocate and promoter of environmental protection and sustainable solutions in the industry and the whole value chain.

The official opening of the GIGA plant is an important milestone in the company's development history, meaning that Tederic's ability to build a world-class plant has reached a new level. At the same time, it also signifies that Tederic has the power to provide global customers with multi-faceted and comprehensive moulding solutions, such as plastic moulding and metal forming. In the future, Tederic's GIGA plant will also provide a strong impetus for Tongxiang to accelerate the goal of building a 100 billion intelligent automotive industry cluster!