#Industry News

Tederic's Ultra Multi-Component IMM Successful Delivery

Tederic's Ultra Multi-Component IMM Successful Delivery

The manufacturing of automotive lighting molds has always been considered one of the most demanding processes in the automotive mold industry. As automotive intelligence and technological evolution continue to advance, the design and functionality of automotive lighting have become increasingly complex, posing higher demands on the automotive mold industry. For a company founded in 1985, specializing in the design and manufacturing of precision automotive lighting molds, the feasibility assessment of mold designs, the compatibility of injection molding machines with molds, and high-precision injection molding are crucial. This company, which focuses on the development and production of various types of molds for automotive lighting components, has now become a renowned mold manufacturer in the industry.

01 Successful Delivery

In the client's production base located in Jiangsu, China. You can find bicolor and multi-color molds, as well as thick-walled light guide molds. Having long served as a supplier of molds to global leading automakers and top automotive lighting providers, the precision, flexibility, and stability of testing equipment have become the primary considerations for customers.

Based on the stringent requirements of the industry, Tederic has always been committed to upgrading its technological capabilities to meet customer needs.

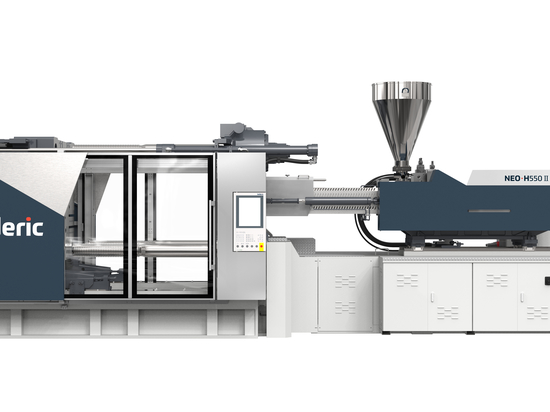

Recently, Tederic successfully delivered an ultra multi-material IMM to the client. The NEO·M2820v Multi-Component IMM with vertical rotary turntable has officially gone into production after delivery, installation, and commissioning. It will be used for mold debugging to produce high-end automotive lighting products in the future. Once again, Tederic has set a new benchmark for China's "intelligent molding" in the international market.

02 Leading the Way with Technology

As a leader in the injection molding equipment industry, Tederic, with its solid technological foundation and relentless spirit of innovation, has always been at the forefront of the industry.

The NEO·M2820v IMM, with its ultra design and unique three injection unit structure, has established a leading position in the industry.

Its rotary table boasts a diameter of up to 2800mm and a load-bearing capacity of up to 30 tons, enabling it to rotate at high speeds from 0-180° with speed, stability, and precise positioning. With a mold loaded, the rotary table can complete a full rotation in just 5 seconds, significantly outperforming industry standards and enhancing production efficiency. It is ideally suited for large-scale, precise, and complex mold and injection molding processes, giving users greater flexibility in mold selection.

This design breakthrough not only meets users' demand for flexibility but also significantly enhances the efficiency and precision of injection molding production, making it an ideal choice for the automotive lighting manufacturing sector. All of this is the best illustration of Tederic's profound understanding of technological innovation and user needs.

03 Customized Solutions

Today, Tederic, with its outstanding technological strength and rich experience, is vividly demonstrating the excellence of domestic substitution. In the field of multi-material injection molding, Tederic's multiple ultra-high-tonnage multi-material injection molding machines are being put into frontline production and continuously gaining recognition and praise from customers.

Tederic's NEO seriesIMM, with their superior performance and precision, are providing high-quality lighting production solutions for emerging EV brands such as Tesla, BYD, Li Auto, and AITO.

We are fully aware that technological leadership is not only the cornerstone of enterprise development but also an important driving force for industry progress. Therefore, Tederic will continue to uphold the principle of "quality first, technology-oriented," drive development through innovation, and build on quality as the foundation to shine even more brightly on the global stage and write a new brilliant chapter.