#Industry News

From precision to excellence, Tederic starts a new era in the production of automotive structural parts

In the long road of automobile development, structural parts have always been the bones supporting the car body, and they are also the first guarantee of safety.

In the long road of automobile development, structural parts have always been the bones supporting the car body, and they are also the first guarantee of safety. Just as muscles and bones are to the human body, structural parts play a vital role in the overall stability and safety of the car.

For a system service provider for automotive exterior parts founded in 1988, the stability and tightness of the injection molding process of structural parts are of paramount importance.

Promote the process of Chinese Auto

Walking into the customer's production base in Jiangsu China, nearly 100 sets of European high-end brand IMM come into view, as if telling the history of providing long-term supporting services for the world's first-line vehicle enterprises. However, with the wave of "domestic substitution of imports" sweeping, the rise of Chinese equipment brands is rapidly changing this pattern.

Nowadays, high-end equipment with high technology content and high added value is at the core of the current manufacturing industry value chain, and Chinese manufacturing equipment brands are achieving technological breakthroughs at a snowballing speed, and their R&D strength is comparable to that of European equipment.

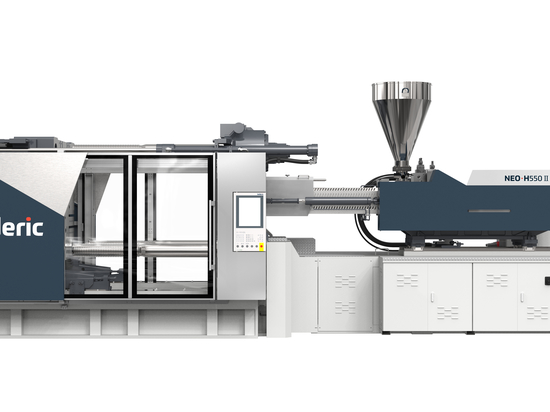

Customers set their sights on domestic injection molding equipment. As a one-stop intelligent injection molding solution provider, Tederic has become the first choice of customers with its high-efficiency, high-precision and more stable characteristics of large-scale two-platen injection molding machine, which has accumulated its expertise over the years.

Accelerate the development of EV brands

The intelligent injection molding solution provided to customers this time is based on NEO · H1700II as the main body, successfully produced the L6 front-end frame. This process is not only the integration of technology and innovation, but also a test of productivity, and finally breaks through many difficulties in product design, precision and safety.

With precise injection control and mold opening and closing accuracy control, coupled with the configuration of high-rigidity two-plate mold shifting slides and double-layer linear guides, the equipment shows more excellent stability in the production process. In addition, in combination with a high-torque electric preform motor and a high-volumetric efficiency gear pump, this solution also brings significant energy savings to the customer, making it highly competitive in the fierce market environment.

It is worth mentioning that at the beginning of September, Li Auto's weekly sales reached 11,300 units, ranking first among new brands in the Chinese market for 19 consecutive weeks. Tederic is helping Chinese EV brands rise at an unstoppable speed with its excellent intelligent manufacturing capabilities.

Tederic is setting a new benchmark for advanced automotive parts injection molding, leading the industry to higher standards and requirements.

Automotive structural parts not only reflect consumers' demands for vehicle safety, but also carry the pursuit of the future of automobile manufacturers. Tederic worked hand-in-hand with the customer to complete this highly complex project, meeting the customer's extremely high requirements for precision and performance.