#Trade Shows & Events

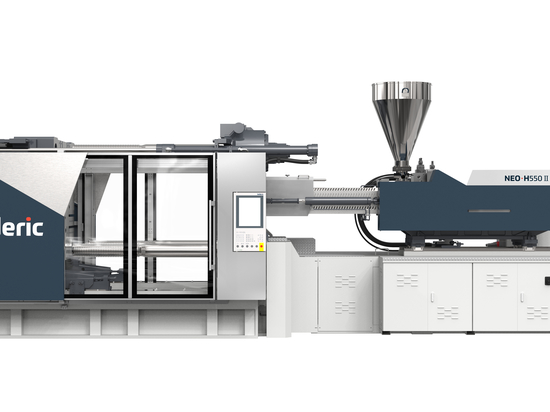

Exhibition| Tederic bring NEO·EII to the FAKUMA2024

On October 15th, the plastics industry exhibition FAKUMA opened in Germany.

At the FAKUMA2024, Tederic showed high-end IMM - the NEO series. The solutions to the challenges of efficiency, resource conservation and sustainability have attracted the attention of many industry professionals.

With the introduction of the new Energy Efficiency Act, the plastics processing sector in Germany will face even greater challenges. How to achieve higher energy efficiency, absolute resource efficiency, consistent process efficiency, and improve the efficiency of plant operations are at the heart of this year's Fakuma.

In order to better respond to the needs of the European market, Tederic established an R&D center in 2022 composed of a local elite team, focusing on innovative technologies and industrial applications in the field of injection molding. We have gradually built a systematic network based in Germany and radiating the entire European market to more accurately identify and meet the needs of European customers.

01 Efficient and low-carbon technology, personalized customization has become a trend

At this exhibition, the NEO·E160II electric IMM demonstrates the entire process with three PC-ASA cup holders as an important part of an automated production cell.

The design of the cup holder can be customized according to customer needs to meet diverse usage scenarios and aesthetic needs, and conforms to the current development trend of environmental protection, personalized customization and sustainability of daily necessities.

In the production process of NEO · E160II, Tederic cooperated with INCOE International Europe to adopt a 3+1 hot runner series mold, which is equipped with a pneumatic 4-way needle gate system and dynamic heat injection mold temperature control. This solution makes the surface of the product smoother, which greatly improves the production efficiency and product quality.

02Intelligent manufacturing solutions to help the transformation and upgrading of the plastics industry

In addition, Tederic exhibited another electric IMM - NEO · E60II, which uses common polypropylene as a raw material to generate a token.

The solution enables the more cost-effective and precise manufacture of small components that require the highest surface quality and detail, while effectively controlling unit costs, opening up new possibilities for mass production.

With the rise of intelligent manufacturing, automation and intelligent solutions have become another highlight of the exhibition. At the exhibition, Tederic also showcased a series of innovative digital solutions and synergies with partners. These solutions are designed to help customers tap into the potential of digitalization, optimize energy consumption, and drive the industry's transition to low-carbon development.

Thomas Strecker, Managing Director of Tederic Germany, said: "It is a pleasure to present two Tederic electric IMM together with the teams in China and Munich: NEO · E160II and NEO · E60II. The machine is equipped with a full set of automation equipment and auxiliary equipment, showing a one-stop high-tech intelligent injection molding solution. We also received a lot of good feedback from the audience and potential customers on site. ”

Tederic focuses on providing automated, intelligent and digital solutions to build its core competitiveness in the field of injection molding. At this FAKUMA exhibition, we believe that with the technical support of the local R&D center and the accurate grasp of the European market demand, Tederic will continue to lead the industry reform and promote the plastic processing in the direction of intelligence and green.