#Industry News

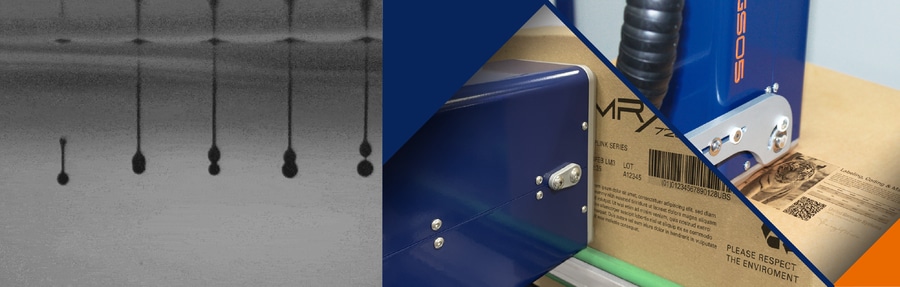

Let's talk about Drop On Demand (DoD) technology.

At United Barcode Systems we have been working with DoD technology in our APLINK printers for years. Find out what this printing method is all about and what its advantages and challenges are.

Drop On Demand (DOD) technology is a printing method in which ink droplets are ejected only when a specific dot needs to be printed. This approach is commonly used in secondary packaging coding due to its ability to print detailed information at lower speeds. There are two main approaches to implementing DOD: thermal and piezoelectric.

In thermal technology, heat is used to generate a vapour bubble that selectively ejects ink droplets. Meanwhile, in piezoelectric technology, a piezoelectric crystal deforms and generates a pressure wave to eject the droplets, allowing precise control over size and speed.

The advantages of DOD include high resolution, ink variety and efficient ink usage, while the challenges it presents relate to print speed, initial cost and satellite droplet formation.

Want to know how UBS has managed to solve most of the DoD's drawbacks? Then click on the link below to view the full article on our website to make sure you don't miss a thing.