#Trade Shows & Events

Valco Melton presents at LabelExpo the new innovative Akura coating solution that combines adhesive application and quality inspection for important cost savings.

Stop by our booth C24 in Hall 6 to see our Akura Hot Melt Coating Solution, our Inspekt range of quality inspection systems, and our newest development BrailleChek Label vision inspection camera.

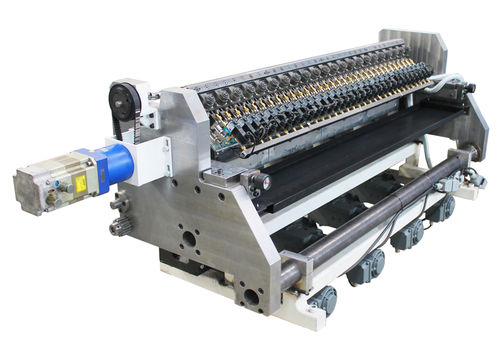

As a global producer of gluing and quality inspection technologies for label manufacturing, Valco Melton offers converters a reliable hot melt system for uniform coatings across the entire web width without the need for manual intervention. With the Akura Hot Melt Coating Solution, label manufacturers ensure better product quality and reduce the risk of production errors and waste, achieving significant cost savings.

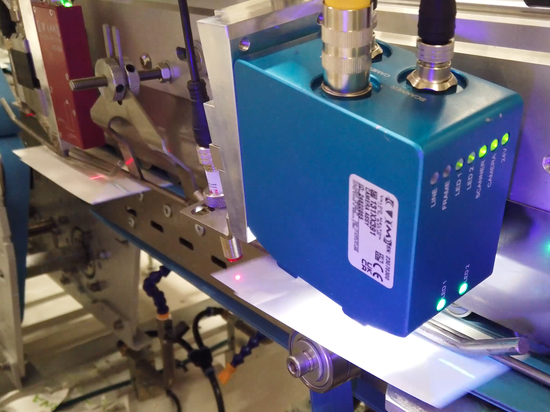

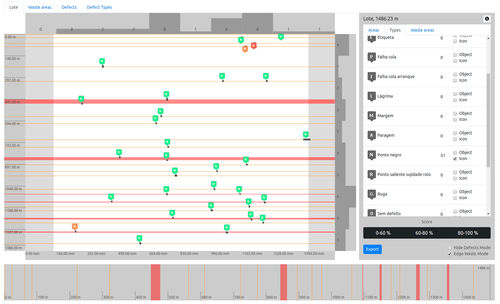

The Akura Solution combines our Akura hot melt coating applicators with our Inspekt range of quality assurance tools. Akura applicators feature independent hydraulic zones, each fed by a gear pump, ensuring an even distribution of adhesive across the web width. The Weight-Inspekt measures the average adhesive grammage of each hydraulic zone, independently from the substrate, and controls it in a closed-loop with gear pumps. It automatically adjusts the adhesive flow for the specific hydraulic zone when deviations are detected, ensuring consistent product quality. The Coat-Inspekt vision inspection system combines real-time error detection with an AI system that automatically classifies all errors into pre-set categories, providing an immediate and intuitive overview of production status. Together with the historical data stored in the system, this brings our users a powerful tool for process analysis and indications on defect positioning for elimination in the following step of the process.

We will also present our BrailleChek label vision inspection system for the first time in Europe. Using high-speed camera technology and custom lighting, BrailleChek examines each Braille dot embossed on the printed side of the label at full production speed, detecting missing or poorly formed dots and registration errors.

Our Coating Team will be at booth C24 in Hall 6 to assist visitors with any questions or projects, exchange ideas, and discuss your industry challenges.