#Industry News

Raising the Bar In Quality Inspection Solutions For The Coating & Converting Industries: Introducing Lumitio by Valco Melton

Lumitio is now Valco Melton’s brand of quality inspection and process management solutions for the coating and converting industries.

Lumitio is a Portuguese company that specializes in the development of industrial IoT solutions. These solutions enable users to gather and analyze production-related data seamlessly integrated into the company’s system architecture.

Leveraging Valco Melton’s expertise in hot melt coating processes, Lumitio by Valco Melton has developed the Inspekt range. This range equips converters with tools for achieving defect-free production processes and efficient resource management.

Unveiling the Inspekt Range

Designed with the requirements of the coating and converting industries, the Inspekt range comprises three solutions, each developed to address a specific quality or process optimization need.

Weight Inspekt grammage control systems measure the adhesive coat weight independently from the substrate thickness. This in-line system controls product grammage in close-loop with the gear pumps on the applicator without stopping the line, thus preventing product waste.

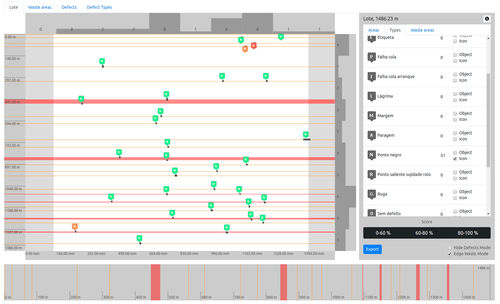

Coat Inspekt vision inspection systems combine real-time error detection with an artificial intelligence system that automatically classifies all errors detected into pre-set categories, providing an immediate and intuitive overview of production status. This visibility and the historical data stored in the system brings users a powerful tool for process analysis and indications on defect positioning for elimination in the following process step.

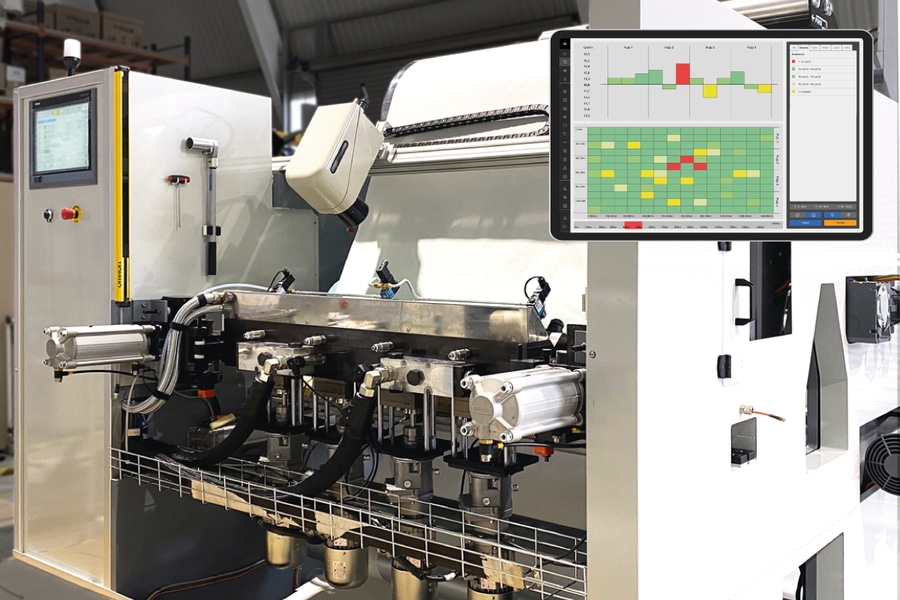

Prod Inspekt helps manufacturers uncover their hidden growth potential. This Manufacturing Execution System (MES) features nine modules that integrate all production-related data into a single platform. Acting as a comprehensive information hub, Prod Inspekt helps align all company areas and inconsistent operational strategies through accurate data, ensuring that every manufacturing process is optimized for success.

Leading the Shift Towards Data-Driven Decision Making

The Inspekt suite of products provides manufacturers in the coating and converting business access to previously inaccessible data and sophisticated analytical tools. The added power enables users to extract precise production insights, empowering informed, data-driven decision-making in today’s intricate business landscape.

One Single Supplier for All Your Hot Melt Coating Needs

With the addition of the Lumitio brand, Valco Melton now serves as your single supplier for any hot melt coating requirements. Specific solutions include the Akura range of applicators to cover any coating and laminating requirements. Whether you require standard applicators with multiple adhesive inputs, metering heads for enhanced adhesive distribution, applicators with interchangeable blades for various applications, or an advanced die with automatic width adjustment, Valco Melton's selections have you covered. Whether you require standard applicators with multiple adhesive inputs, metering heads for enhanced adhesive distribution, applicators with interchangeable blades for various applications, or advanced dies with automatic width adjustment, the Akura series has you covered. A selection of pre-melters (drum unloaders or extruders), buffer tanks, and melters are available for all melting needs.

Paired with an unbeatable after-sales and technical support network and lab testing facilities in our Global and European Headquarters, Valco Melton is your trusted partner in the coating and converting industries.