#Industry News

Valco Melton’s bottom-up gluing station for side-seam gluing ensures a clean application and significant adhesive savings.

Valco Melton has established the bottom-up gluing station as one of the most transformative solutions for its clients' production lines.

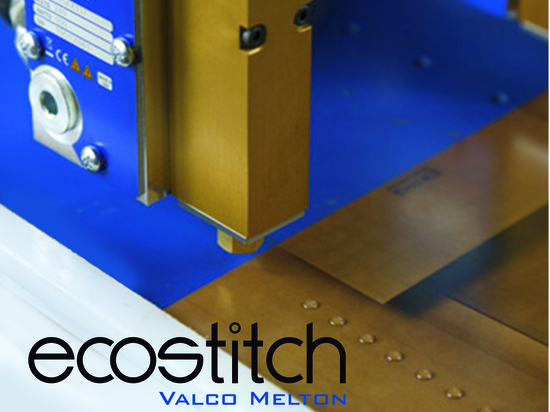

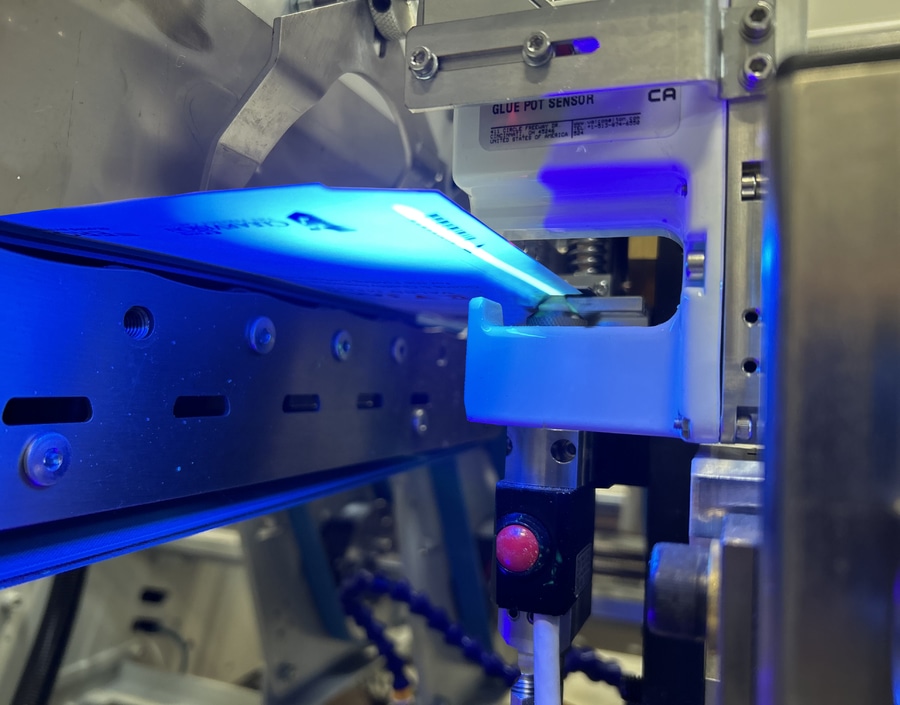

An international leader in the design and development of cold glue, hot melt application, and quality assurance technologies, Valco Melton has established the bottom-up gluing station as one of the most transformative solutions for its clients' production lines. Offering clean and precise gluing application, the bottom-up gluing station was designed to replace glue wheels, open systems that resulted in excessive adhesive waste and required daily cleaning and maintenance to prevent the adhesive from drying. The bottom-up station, on the other hand, is a closed-circuit system that requires minimal maintenance and consumes only the necessary adhesive to glue the cartons. This means that time and effort previously spent on daily cleaning can now be devoted to carton production or other tasks. The station is equipped with an electric glue valve that allows precise glue patterns applications at speeds of up to 700m/min. This ensures the exact amount of adhesive is used, minimizing waste. “Additionally, our stations are able to apply glue dot patterns instead of traditional beads, further increasing savings and significantly reducing costs”, says Markus Bohnenkamp, North Europe Sales Director.

The advantages of the bottom-up station have been reaffirmed over time. In addition to adhesive savings, they provide a much cleaner system than open glue pots, which, when running at high speeds, can splatter glue drops, dirtying the surrounding and potentially impacting the product quality and the proper functioning of other devices on the line. Closed circuit systems are here to stay. As Carlo Zucchi, South Europe Sales Director, states, “We have clients who started using bottom-up stations over 10 years ago and they still work every day since and with great satisfaction. Many of them have gradually replaced the rest of their glue pots with our bottom-up stations. They no longer want to use glue wheels, as they no longer need to spend time on daily cleaning and maintenance.”

The gluing station can be complemented with the CGS-40S sensor for side-seam pattern inspection. The complete system can be installed quickly and cleanly in virtually any folder-gluer, either on the operator side or on the drive side.

A clean and precise application, significant adhesive savings, and the end of daily maintenance tasks make Valco Melton’s bottom-up gluing station a competitive solution that improves product quality, provides important economic savings, and increases the productivity and competitiveness of the production line.