#Trade Shows & Events

Valco Melton to Showcase Latest Hot Melt Coating Solutions at ICE Europe 2025

As a trusted leader in the coating and converting industries, Valco Melton is excited to return to ICE Europe, the industry's premier converting event.

We invite visitors to join us at Stand 1114 in Hall A5, where we'll demonstrate our innovative hot melt coating and vision inspection solutions: the Akura Hot Melt Coating Solution and Inspekt quality assurance tools.

The Akura Hot Melt Coating Solution is engineered to deliver consistent adhesive coating across the entire web width without manual intervention. By eliminating coating inconsistencies, this system not only ensures superior product quality but also minimizes production errors and waste, resulting in meaningful cost savings for converters.

The Akura Solution seamlessly integrates our Akura coating applicators and the Inspekt quality assurance suite. The applicators feature multiple independent hydraulic zones, each precisely controlled by a dedicated gear pump to ensure uniform adhesive distribution. This technology works in harmony with our Weight-Inspekt grammage control system, creating a closed-loop system that maintains exact adhesive grammage across each hydraulic zone, automatically correcting the pump rate to avoid any deviations, maintaining consistent quality.

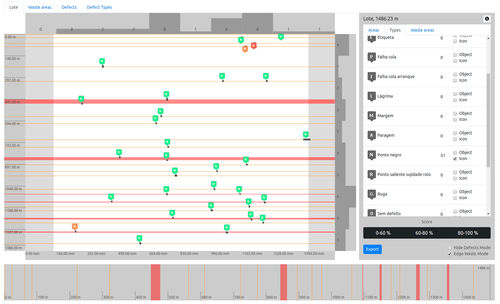

The Inspekt quality assurance suite represents the cutting edge of defect prevention technology. Our Weight-Inspekt system offers precise adhesive coat weight measurement independent of substrate thickness, working seamlessly with the applicator's gear pumps to maintain optimal grammage without production interruptions. The Coat-Inspekt vision system combines real-time detection with advanced AI to identify and categorize defects, providing operators with instant production status updates. Together with comprehensive historical data tracking, these tools enable detailed process analysis and precise defect location for downstream processing.

Product traceability remains a key focus of our solutions. Each roll produced comes with detailed documentation, including a comprehensive roll map showing the position, characteristics, and images of detected defects from our Coat-Inspekt system. The reports also track adhesive distribution patterns and record the specific recipe parameters used in production, ensuring complete process transparency.

Our commitment to comprehensive solutions sets us apart in the industry. From adhesive melting and dosing to application, web handling, and quality inspection, we provide all the essential components for successful hot melt coating operations. Our product range includes versatile pre-melters, buffer tanks, and melters designed to meet diverse melting requirements. The LP Series Hot Melt Coating Lines excel at coating and laminating multiple materials, producing high-quality laminated rolls for various industries and manufacturing processes.

Visitors to our ICE Europe 2025 booth will experience these innovations through detailed video demonstrations, with our technical experts available to provide in-depth explanations and address specific questions. We look forward to showing you how our solutions can enhance your production efficiency and product quality.