#Product Trends

Varvel is bending over backwards

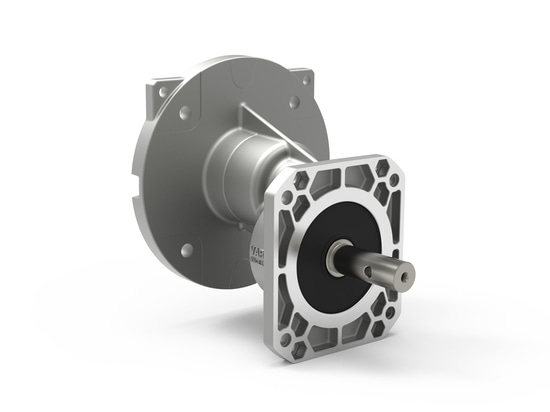

Varvel SpA, appreciated worldwide for the high degree of innovation, has a solid experience in designing and manufacturing bevel helical gearboxes dedicated to all drives.

Market analysis performed by Varvel over recent years highlighted many large applications requiring lower reduction ratios with a maximum of about 1/50 with the consequent necessity of straight supplying to the end user.

The company has therefore decided to design a new range of bevel helical gearboxes called RO2. The whole design was carried out by the internal R&D department by using the most modern gear calculation and modeling with the aid of structural analysis programs to check housing stress and deformation.

The major novelty of this gearbox series is the reduction ratio with two gear stages, one cylindrical and one conical. The gearbox range starts from the size RO2 with torque of 120 Nm.

The present market, always with the objective of increasing the transmission efficiency, requires - also for low torque values - helical bevel gear units instead of the more traditional worm.

This prompted the new product that will be exposed with great prominence at the Hanover Fair 2015, i.e. the right angle gearbox range RO2.

The new bevel/helical gearboxes with two gear reduction stages includes four sizes:

RO2 - torque 120 Nm - max 25 mm. hollow shaft

RO12 - torque 200 Nm - max 30 mm. hollow shaft

RO22 - torque 330 Nm - max 35 mm. hollow shaft

RO32 - torque 550 Nm - max 40 mm. hollow shaft

This first approach makes evident a significant feature of the new series: on average, torque capacity is higher by about 20% to 30% compared with that of key competitors on the market.

Another notable technical feature is the selection of reduction ratios: gear ratios are from 1/5.2 to 1/51.5 for a total of twenty ratios so as to fulfil the majority of speeds asked by the market.

A third technical feature is the monolithic structure of the gear housing: this is a key issue for this type of gearboxes, as usually the housing is the only connection to the machine frame.

Having made the gear housing monolithic and with more fixing holes to the frame than the primary competition, a great benefit has brought in the torsional rigidity of the gearbox and consequently in fixing to the user application.