#Product Trends

Endless improvement

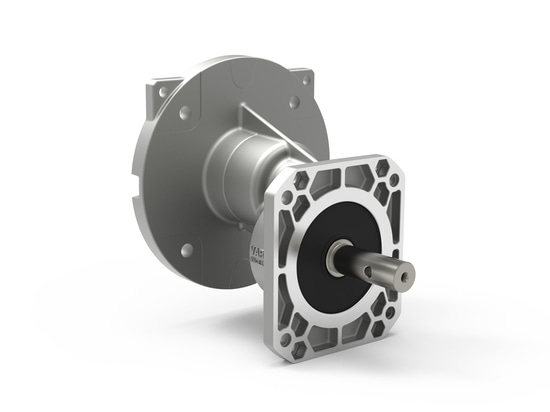

Varvel''s R&D department has improved further the gearbox noise level to match the market requests of this type of application.

This was achieved by cutting the input pinion direct on motor shaft instead of former fitting.

This way, alignment or concentricity errors are avoided, contrary wise of what might occur with the previous system.

The integrated pinion shaft is available in two reduction ratios (3.95 and 8.50) allowing a wide range of ratios (from 41.12 to 271.16).

The available motor sizes are 60W, 90W and 120W according to the required reduction ratio.

The gears are calculated for a maximum output torque of 60Nm and 10,000 hour lifetime.

The hollow output shaft is available with bores of ø17 and ø20 mm with standard keyway, and ø25mm without keyway.

The housing is designed for shaft mounting fitting with 4x ø8.5mm through holes, interchangeable with the main competitors.

Four additional not-through holes on PCD 85mm are available for self-threading M8 screws to match RT/RS50 output flange mounting.

Varvel''s corporate policy is based on its belief that a good product is not merely enough but it must be also made according to what the market is asking for.

RB13 positive performance underlines Varvel''s commitment in optimal solutions for different markets in addition to the strict ‘Made in Italy'' criterion, the highest quality, the strong supply chain and the logistics capability further strengthened by the new branch opening in 2012 in Settimo Milanese (MI).