#Industry News

Industry 4.0 in the agricultural sector

Optimising the harvesting process with advanced sensor technology in combine harvesters

Agriculture has changed significantly in the wake of advancing digitalisation. Farmers used to rely on manual skills and experience, but technological advances have led to a major change. The integration of advanced sensor technologies to measure heights, positions, lengths and distances in combine harvesters and agricultural machinery marks another decisive step towards more sustainable and efficient field management and harvesting.

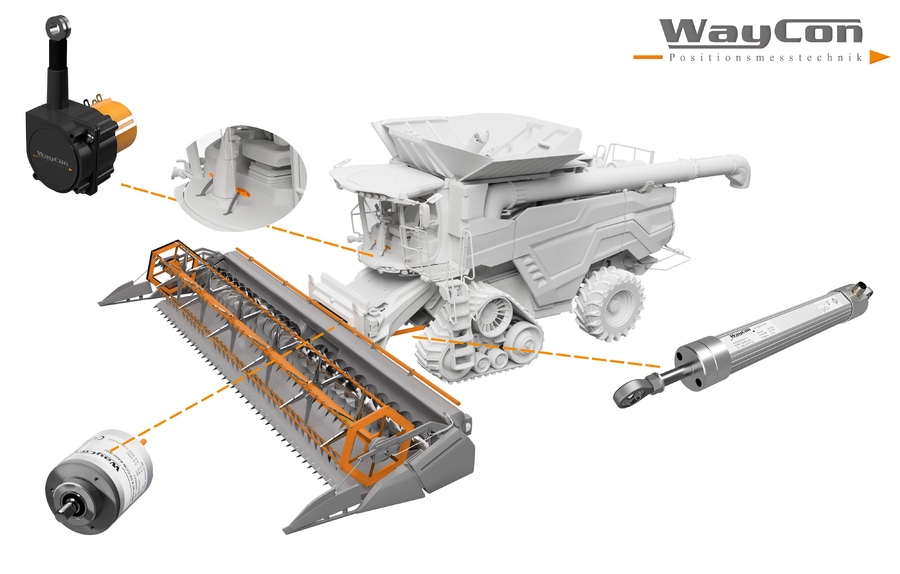

The description of the harvesting process illustrates the complexity of agricultural work. Combine harvesters, once simple harvesting machines, are developing into high-tech devices thanks to technological innovations. The front-rotating reel and the precise cutting unit, controlled by sensors, significantly improve efficiency. Modern sensors, such as the WPH angle rotary sensor from WayCon, play a key role in monitoring and controlling the harvest headers. The detailed development of harvest headers has already played a key role in high harvesting yields.

The enormous challenges that combine harvesters face in every harvesting process require continuous adjustments. More diverse crop rotations, cultivation and harvests increase the need for careful design of harvest headers on combine harvesters. Modern sensors such as the WPH angle transmitter are indispensable instruments for measuring the reel position. The WPH rotary transducer, with its wear-free Hall effect sensor element and increased protection rating IP67, is specially designed for harsh environments.

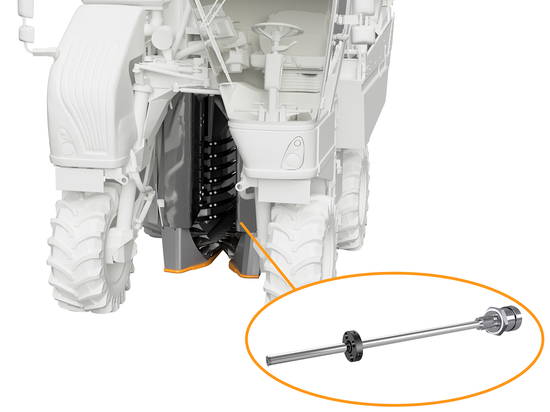

Position sensors, such as the SXM30 draw-wire sensor, precisely detect the accelerator pedal position to ensure a constant feed speed. The exact height adjustment of cutting units by the WPH angle sensor enables a safe and efficient work process. The WPH angle sensor's standard signals of 0.5...4.5 V or 0...5 V enable quick and easy installation. This automation is not only efficient, but also contributes to safety and comfort for the farmer. The crop flow control in combination with flexible belt cutterbars and ground tracking reduce crop loss and increase yields. When adapting to uneven ground, it is also necessary to make transverse adjustments to the draper attachments, which is done using complex hydraulic linkages. The lifting movements on the hydraulic cylinders are measured externally using the LZW-IP linear potentiometer or internally in the cylinder using the WayCon MSB magnetostrictive transducer.

The technology goes beyond mechanical harvesting and optimises resource consumption. The integration of sensors and increasing autonomy in off-highway machines leads to an increase in productivity, savings in energy and operating resources as well as an improvement in work results. The development of sensor technology in combine harvesters represents an impressive evolution in agriculture and agribusiness.

Does the future of modern agriculture lie in the autonomous navigation of harvesters?

Sensors that continuously record the surroundings enable precise control, collisions are avoided and optimum harvesting routes are planned. Autonomous navigation leads to more efficient routes, minimises fuel consumption and reduces overall working time. This not only leads to cost savings, but also contributes to sustainability in agriculture. WayCon Positionsmesstechnik GmbH is keeping a close eye on this development and is happy to assist you as a specialist in the field of linear measuring sensor technology.