#Product Trends

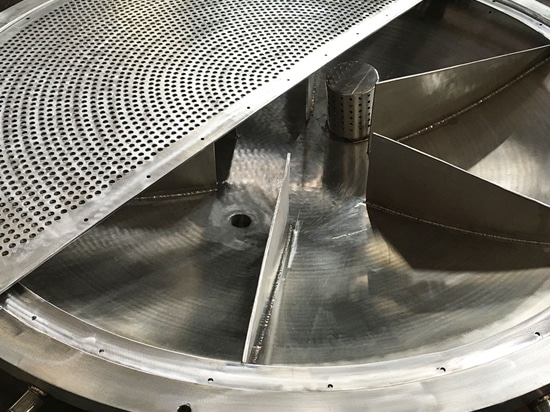

New Multi-functional Extraction Tank

Extracting Rose Essential Oil from Roses

1. Water vapor distillation

Water vapor distillation is a commonly used method for extracting essential oils from plants. The distillation equipment has a large volume, and flowers concentrated in the flowering period can be processed in large quantities, and the operation is simple and low-cost, so it is the main method for extracting essential oils from fresh flowers. This method is suitable for the extraction of active ingredients that are volatile, can be vaporized with water vapor without being destroyed, do not react with water, and are difficult to dissolve in water.

Will be fresh or dry treatment of aromatic plant raw materials into the distiller, add water to heat together, under the action of steam, the petals of terpenes, alcohols, lipids and other essential oils and water vapor evaporation, containing essential oils of the water vapor through the conduit to collect the cooling of the steam will be cooled into a liquid, and then in accordance with the difference in the density of the water and the essential oils are separated out. Using the essential oil components volatile, insoluble in water and do not react with water characteristics, condensation collection, and finally get the essential oil.

The distillation process requires careful control of temperature and time to ensure that only the pure aroma components of the rose are extracted.

The resulting rose essential oil has a relatively fresh, light odor and holds its fragrance for about 2 hours.

2. Solvent extraction method

Organic solvent extraction method is the use of volatile organic solvents, continuous reflux extraction or cold immersion, hot immersion extraction, etc. will dissolve the plant components, and then through the distillation of the extracted liquid or decompression distillation, etc. to remove the solvent can be obtained from the crude essential oil. The solvent extraction method is used to extract natural flavors from plant materials, and the yield of flavors obtained by this method is significantly increased.

Generally, the solvent and plant material into the extractor mixed extraction, so that the volatile substances dissolved in the solvent; and then filtered; subsequently, evaporation and concentration of the solvent to get the filtrate, the concentrate is called extract (wax, a mixture of essential oils); the extract is dissolved in ethanol, low-temperature filtration to remove impurities; and finally, evaporation of ethanol to get the essential oils.

Can be extracted to a more complete rose odor, more intense, calm, with a heavier sense of wood, holding time of about 5 hours.