#Industry News

Application of power amplifier in piezoelectric actuated droplet injection process

Name of experiment:experimental study of piezoelectric actuated droplet ejection behavior under coax

Name of experiment:experimental study of piezoelectric actuated droplet ejection behavior under coaxial airflow

Experiment content:

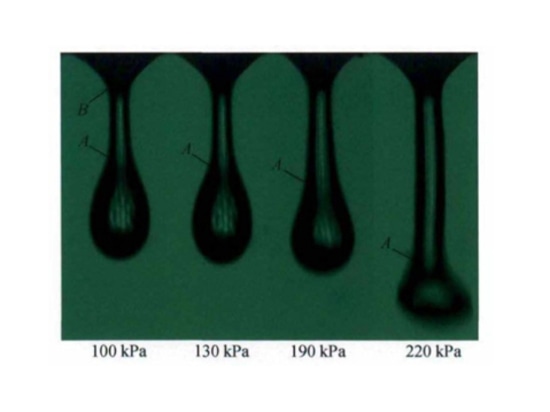

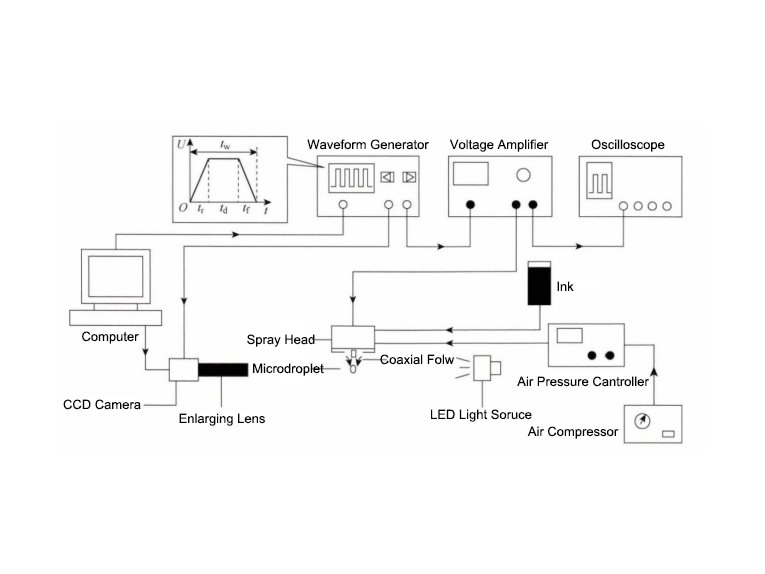

In this paper, a piezoelectric droplet nozzle with coaxial jet groove is designed and manufactured, and a droplet injection and observation system is constructed. A bi-polar trapezoidal wave was used as the piezoelectric driving-droplet waveform, and the droplet images at different moments were obtained by a charge coupling camera based on the repeatability of the droplet ejection process. At the same time, the droplet ejection behavior under the action of coaxial airflow was studied.

Purpose of experiment:in order to investigate the effect of coaxial airflow on piezoelectric droplet spraying process

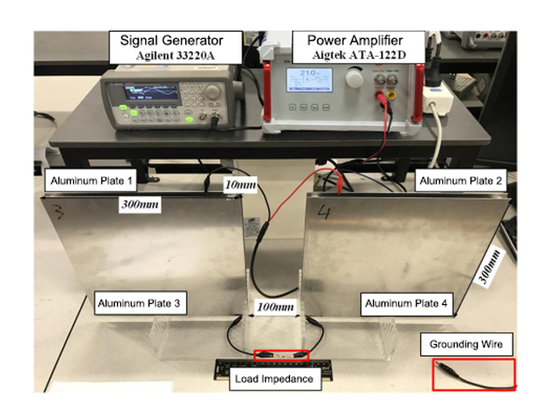

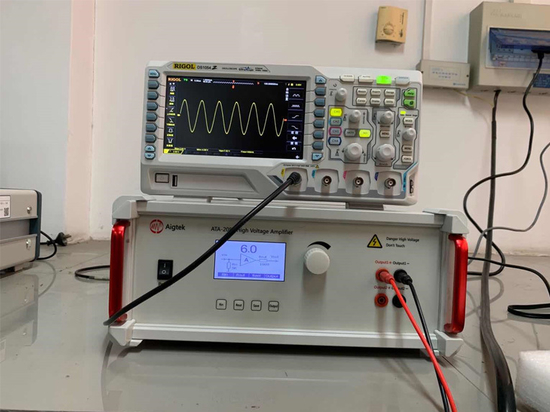

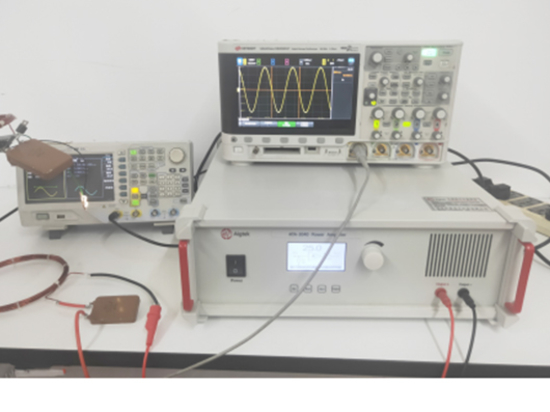

Test equipment:piezoelectric dropper nozzle, signal generator, ATA-2032 power amplifier, oscilloscope, LED light source, CCD camera, magnifying glass, etc.

Experimental process:

By using the inverse piezoelectric effect, the piezoelectric ceramic plate is stimulated by the pulse voltage to produce mechanical vibration, and the volume of the liquid storage cavity changes to drive the droplets from the nozzle. Waveform signals are mainly generated by signal generator, amplified by a power amplifier to drive the piezoelectric plate, and then connected to an oscilloscope to display the amplified waveform signal in real time. The waveform signals are bipolar trapezoidal waves.

Based on the good repeatability between different droplets at the same time in the process of droplet spraying, a charge-coupled device (CCD) camera was used in the droplet observation system, and the droplet images at different times were obtained by accurately adjusting the lag time of similar exposure relative to droplet spraying during the experiment.

Result of experiment:

With the increase of coaxial airflow intensity, the following conclusions will appear:

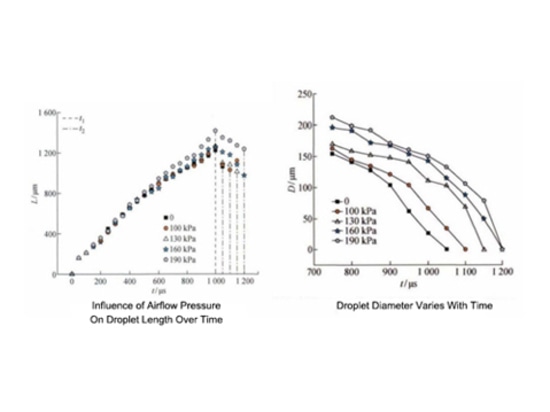

1. In the formation stage, the droplet extension length increases and the droplet head volume decreases.

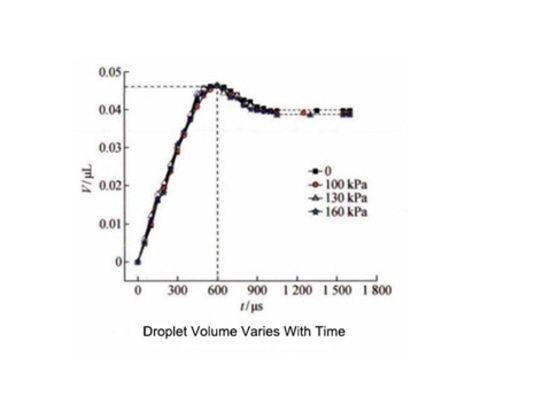

2. The fracture time of the droplet at the nozzle exit is not affected by coaxial airflow, but the fracture time of the droplet at the head and tail during flight is delayed.

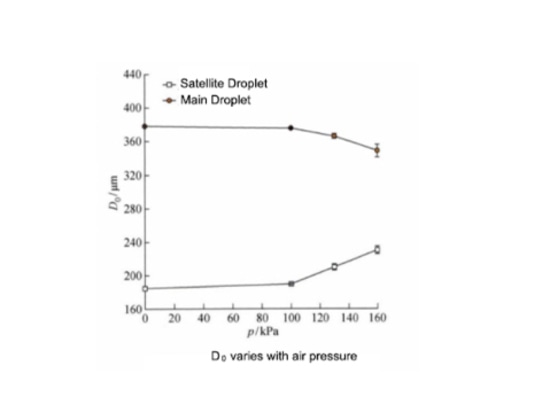

3. The final total volume of droplets at the jet decreased slightly, the volume of main droplets decreased, and the volume of satellite droplets increased.

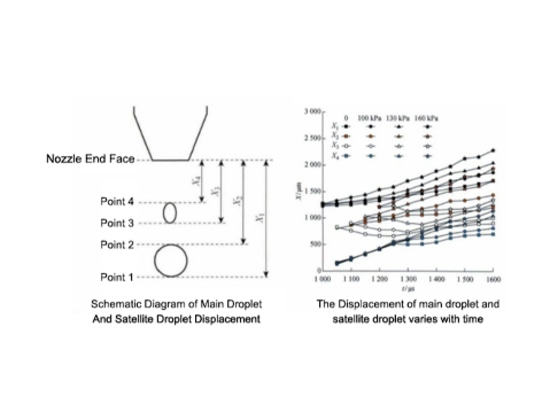

4. The displacement of the main droplet and the satellite droplet increased at the same time, and the velocity of the head and the end of the droplet increased, and the fluctuation and frequency of the end velocity decreased.

5. The main droplet and satellite droplet are more flat, and the equivalent diameter of the main droplet decreases while the equivalent diameter of the satellite droplet increases.