#Industry News

Discussion on Fiber Coil Test

Discussion on Fiber Coil Test

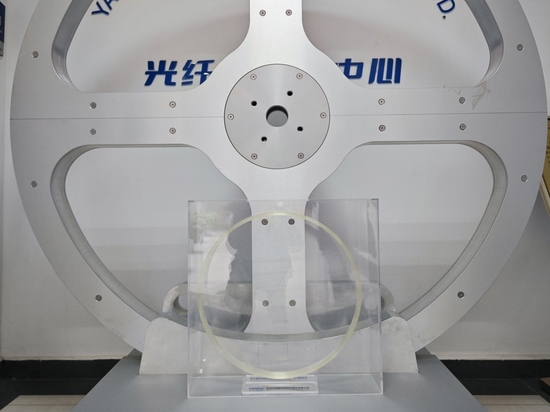

In 1976, the University of Utah proposed fiber optic gyroscopes (FOG) for the first time, marking the birth of the second generation of optical gyroscopes. After 45 years of development, the size of the global FOG market has reached 3.8 billion. The fiber coil (or “polarization-maintaining fiber coil” or “fiber sensing coil”) is the core sensing element of the FOG. Its function is to convert the angular velocity signal of the object motion into the optical phase signal, and then convert the optical phase signal into electrical signal output through other components of the FOG. Therefore, it can be said that the fiber coil is the start of the sensing signal of the FOG, and the quality of the fiber coil directly determines the upper limit of the performance of the FOG.

1. Principle of FOG

What kind of fiber coil is a good coil? How to evaluate a fiber coil? These two problems are the problems that need to be solved in the fiber coil test.

In the spirit of pragmatism, the evaluation of the fiber coil needs to start from its usefulness. At present, most fiber coils are used in interferometric FOG. Its fundamental principle is to input two beams of light from two pigtails into the fiber coil at the same time. Due to the Sagnac effect caused by the rotation of the fiber coil in the inertial space, one beam of light will be output from the opposite pigtail faster than the other. By measuring the time difference between the two beams of light output from the fiber coil, the angular velocity of the fiber coil relative to the inertial space rotation can be judged.

Since light is a kind of wave, the time difference φs can also be expressed as a phase difference, and its relational expression with the angular velocity Ω of the fiber coil is as follows:

φ₅ =K Ω+ φ₀

Where K is the scale factor of the fiber coil, φ₀ is the zero offset of the fiber coil.

The signal conversion law of the fiber coil can be seen from the above formula. In an ideal state, if the scale factor is constant and there is no zero offset, the relationship between the angular velocity and phase difference can be expressed as a simple positive proportional relationship; and the larger the scale factor, the greater the phase difference caused by the same input angular velocity through the fiber coil, and the higher the theoretical resolution upper limit of the FOG. However, in reality, the scale factor and zero offset will fluctuate or offset under the influence of environmental factors, which will affect the final measurement. The fiber coil test needs to measure the degree of performance change of the fiber coil affected by environmental factors. Determine whether it can meet the requirements of the FOG under the required working environment.

2. Fiber coil test

There are several types of current fiber coil tests: overall dimension inspection, optical performance inspection, and FOG performance inspection. Overall dimension inspection includes measuring the inner diameter, outer diameter and height of the fiber coil; optical performance inspection includes OTDR test, normal temperature crosstalk loss test, constant temperature crosstalk loss test, full temperature crosstalk loss test; FOG performance test includes zero-bias peak-to-peak value test (or system test), magnetic field sensitivity test, scale/misalignment angle test, start-up test.

The overall dimension inspection is to ensure that the overall dimensions of the fiber coil meet the standard because the overall dimensions of the fiber coil are directly related to the assembly process of the FOG.

The optical performance test is mainly to verify whether the optical performance of the polarization-maintaining fiber can still meet the basic usage requirements of the FOG after being wound into a coil.

The OTDR test in the optical fiber performance test, on the one hand, will detect the coil length data of the fiber coil, and on the other hand, will detect whether there are breakpoints or high loss points in the fiber coil to be tested. The breakpoints will form a high reflection peak after lighting, and the reflection peak will cause very serious interference to the operation of the FOG, which must be avoided. The high loss point is often the more serious stress point and is very easy to fracture during the subsequent aging process, which also must be eliminated.

The normal temperature crosstalk loss test is a simplified version of the constant temperature crosstalk loss test, and the constant temperature crosstalk loss test is a low-cost version of the full temperature crosstalk loss test. The full temperature crosstalk loss test is to test the crosstalk and loss changes of the fiber coil at full temperature. Crosstalk is sometimes replaced by extinction ratio. It is necessary to recognize here that the crosstalk is a negative number, which refers to the ratio of the light intensity on the secondary polarization axis to the light intensity on the primary polarization axis of the emitted light. In contrast, the extinction ratio is a positive value, which refers to the ratio of the light intensity on the primary polarization axis to the light intensity on the secondary polarization axis of the outgoing light. The physical meaning of crosstalk and extinction ratio is the polarization-maintaining ability of the fiber coil to incident ray polarized light. In general, the lower the crosstalk value, the greater the extinction ratio, the better the polarization-maintaining ability of the fiber coil, the higher the signal-to-noise ratio of the FOG signal, and the better the performance of the FOG. Full temperature refers to testing the entire working temperature of the fiber coil, constant temperature refers to testing at a specific temperature point, and normal temperature refers to testing at room temperature of 25℃.

The above are all tests for the optical performance of the fiber coil. Although these optical properties will more or less affect the operation of the FOG, it is still too rough to judge the performance of the fiber coil in the FOG application.

FOG performance inspection is a test that truly evaluates the performance of the fiber coil in FOG applications. Each of its projects requires the fusion of the fiber coil and the fiber coil test system to form a temporary FOG, and then various environmental factors are applied to the FOG to evaluate the FOG performance of the fiber coil.

The zero-bias peak-to-peak test is the zero-bi as drift of the FOG at full temperature. On the one hand, it can output the zero-bias peak-to-peak value as the performance index of the fiber coil to evaluate the FOG performance of the fiber coil at full temperature. On the one hand, it can also test the zero-bias change curve of the fiber coil over the entire operating temperature range to evaluate whether the fiber coil has defects at a certain temperature point. At present, the zero-bias peak-to-peak value is the main index for evaluating the FOG performance of the fiber coil.

The magnetic field sensitivity test is a test to evaluate the working stability of the fiber coil under the interference of a magnetic field. During the test, the magnetic field applied on the fiber coil needs to be continuously rotated, and then the range of the zero-bias drift of the FOG is tested as the output of the magnetic field sensitivity. Its fundamental purpose is to judge how much geomagnetism will affect the FOG.

The scale/misalignment angle test measures the change of the scale factor and misalignment angle at the full temperature of the fiber coil. The scale factor is the Kvalue as described above, and the misalignment angle is the deviation angle between the angular velocity-sensitive axis of the fiber coil and the vertical axis of the fiber coil installation surface. The change of the scale factor and misalignment angle will directly affect the measurement accuracy of the FOG.

The start-up test is relatively special. It measures the maximum zero-bi as drift caused by the internal thermal instability after the FOG is started. This test will simulate the uneven thermal field environment after the start-up of the FOG for the fiber coil, and then test the drift of the zero-bias.

3. Conclusion

The above is the current fiber coil test scheme. However, referring to the description of other sensor parameters, the test of the fiber coils hall provide a standard value under normal temperature and pressure, as well as the fluctuation range or correlation coefficient of the measurement value affected by a single factor. However, most FOG manufacturers do not conduct a special measurement for fiber coils, but install them directly on the FOG after verifying the loss and extinction ratio of the fiber coil, and then determine the quality of the fiber coil based on the test conditions of the FOG. If the test result is not good, directly replace the fiber coil or other accessories of the FOG, and then conduct the test to determine the cause of the quality problem. For the users of the fiber coil, this test saves the cost of testing the fiber coil, and the test results are more accurate. However, for the FOG manufacturers, the assembly of the FOG introduces many unnecessary factors, such as the handling of fiber coil pigtails, the quality of the melting point, and the thermal field of the FOG. The performance problems caused by these other influencing factors may be solved by re-assembly once, but the results caused by them need to be borne by the fiber coil, and there is a certain disconnect between the tested FOG performance indexes and the production of the fiber coil, and it is difficult to directly guide the production of the fiber coil. Therefore, for fiber coil manufacturers, this test method is not optimal. However, a standardized optical fiber coil test process has not yet been formed. The test of fiber coils is still carried out according to customer needs, and the test standards of fiber coils are still in the groping and exploration stage.