#Industry News

Large-Core Optical Fiber Technology for High-Energy Laser Transmission

Large-Core Optical Fiber Technology for High-Energy Laser Transmission

Energy Transmission Fiber: A Key Tool for High-Energy Laser Output

Following atomic energy, computers, and semiconductors, lasers are another major achievement of the 20th century. With excellent directivity, monochromaticity, coherence, and high brightness, lasers are widely used in industries like manufacturing, agriculture, communications, entertainment, healthcare, research, and defense. Laser technology has become an integral part of the high-tech industry chain in the information age.

Since their invention, lasers have been closely linked to military technology. Laser processing applications, such as laser cutting, welding, and surface heat treatment, have consistently driven lasers toward higher power levels. Today, research on high-power lasers has achieved significant progress. To safely, efficiently, and flexibly transmit high-energy lasers over long distances, silica-based energy transmission fibers are essential, making fiber technology a critical area of study.

Energy Transmission Fiber

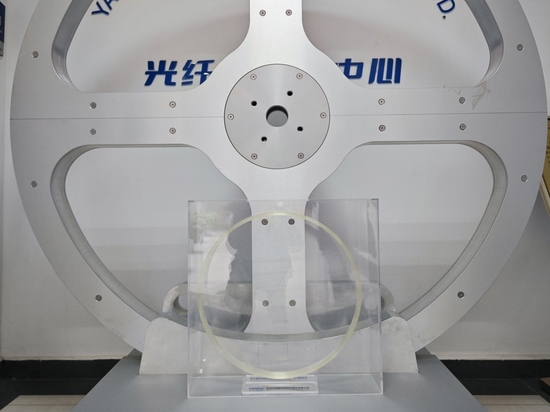

Energy transmission fiber, used to transmit laser energy, has excellent characteristics such as high power transmission, low loss, good flexibility, and high damage threshold. When combined with energy transmission components, these fibers can precisely direct light energy to target areas, playing a vital role in laser applications. Common laser energy transmission fibers on the market are mainly large-core fibers made of quartz glass, including the following types: conventional large-core fiber, special geometric endface large-core fiber, and hollow-core fiber.

Laser Energy Transmission Fiber

Why Choose Quartz Glass as a Material?

Laser transmission fibers, like traditional communication fibers, use quartz glass as their primary material. Quartz glass is ideal for several reasons: it is abundant and inexpensive, being derived from silica, the main component of sand. With just one kilogram of high-purity quartz glass, tens of thousands of kilometers of fiber can be produced, providing significant cost and strategic advantages. Additionally, quartz glass has high light transmittance, mechanical strength, and chemical stability, making it an excellent transmission medium. Quartz can also be doped with various elements to achieve different optical properties, laying the foundation for further development.

Types and Structural Designs of Large-Core Transmission Fiber

Conventional Large-Core Fiber Large-core fiber, similar in structure to single-mode communication fiber, consists of a core and a cladding, with a core diameter typically over 50 μm (compared to 9-10 μm in single-mode fiber). This large core enables high coupling efficiency and energy transmission. The cladding material can be plastic or fluorine-doped quartz, depending on the application. Plastic cladding offers high tensile strength and radiation resistance, suitable for power transmission, short-distance communication, medical lasers, and fiber-optic lighting. Fluorine-doped quartz cladding, with its high bandwidth and low loss, is used in fiber sensors, optical equipment connectors, long-distance communication, and cable television transmission.

Special Geometric Endface Large-Core Fiber Special geometric endface large-core fibers have non-circular cores (e.g., square, polygonal, annular, or elliptical) to meet specific application needs. For example, square-core fiber, with its square or rectangular core, improves coupling efficiency with laser diodes. Square-core fibers can also transform Gaussian laser beams into flat-top beams, beneficial in laser cleaning, cutting, or marking by reducing surface damage.

Large-core annular fibers, with an annular core surrounding the central core, provide solutions to spatter issues in laser welding of profiles like stainless steel or aluminum. This "bullseye" ring spot controls the heat-affected zone, reducing spatter and improving weld quality.

Hollow-Core Fiber Unlike solid-core fibers, hollow-core photonic crystal fibers (HC-PCF) offer unique advantages for laser energy transmission. With an air-filled core, HC-PCFs avoid absorption and reflection losses during laser coupling. The high uniformity of air as a transmission medium minimizes scattering losses, ensures high-quality beam output, and has a high energy damage threshold with good heat dissipation. Although hollow-core fibers have some drawbacks like limited bend resistance and a small numerical aperture, their benefits make them a promising type of energy transmission fiber.

Based on light conduction principles, hollow-core fibers can be classified into hollow-core bandgap fibers (HC-PBGF) and hollow-core anti-resonant fibers (HC-ARF).

Hollow-Core Bandgap Fiber (HC-PBGF): These fibers guide light using the photonic bandgap principle, with a cladding made of periodic air holes arranged in a photonic bandgap structure. Light within the bandgap range is confined within the air core.

Hollow-Core Anti-Resonant Fiber (HC-ARF): These fibers use the anti-resonant reflection waveguide principle, with high-refractive-index quartz in the cladding and low-refractive-index air. Surrounding the air core with several quartz capillaries, HC-ARFs confine light within the air core by reflecting non-resonant light back. The resonant wavelength is determined by the quartz capillary thickness and resonant order.