#Industry News

Energy Transmission Fiber Optic Connection and Application

Energy Transmission Fiber Optic Connection and Application

The application of energy transmission fiber optics in lasers is primarily measured by its coupling efficiency with the laser, or the fiber's laser transmission efficiency (which can also be represented by insertion loss or connection loss). This includes the connection between the laser and the energy transmission fiber, as well as connections between energy transmission fibers themselves or between energy transmission fibers and ordinary single-mode fibers.

Over several decades of commercialization, the connection of conventional large-core fibers has become as straightforward as that of ordinary single-mode fibers, thanks to commercially available large-core splicing machines. However, for large-core specialty geometrical fibers, which have core diameters and structures different from ordinary single-mode fibers and may have varying requirements depending on the application, the connection methods are generally more complex.

For example, in applications involving laser fiber bundle components, a square-core fiber is used to combine the outputs of multiple semiconductor laser modules into a single square fiber, to achieve higher laser energy output. Large-core hollow-core fibers, due to their special cladding capillary structure, are prone to collapse and deformation during splicing. Moreover, the mode field diameter of hollow-core fibers often differs from that of ordinary single-mode fibers, resulting in high splice loss or even failure when spliced directly. Thus, ensuring a structurally intact, low-loss, and consistent transmission characteristic of the hollow-core fiber after splicing is a key challenge for its practical use.

In 2016, J.R. Hayes and colleagues from the Optoelectronics Research Centre at the University of Southampton introduced a transitional fiber with mode field matching between single-mode fiber and hollow-core anti-resonant photonic crystal fiber. This achieved a total splice loss of 2.1 dB between single-mode fiber, hollow-core anti-resonant photonic crystal fiber, and back to single-mode fiber[5]. In 2018, Professor Wang Yingying’s team from Beijing University of Technology improved this method, reducing the splice loss between hollow-core bandgap photonic crystal fibers and single-mode fibers to 0.844 dB[6]. In 2021, Professor Xiao Limin’s team at Fudan University further reduced the total splice loss between single-mode fiber, hollow-core anti-resonant fiber, and back to single-mode fiber to 0.88 dB.

Regarding the coupling connection between the laser source and energy transmission fiber, there are mainly two methods:

1.Direct Coupling: The fiber end is installed close to the laser source, allowing the generated laser to couple directly into the fiber. To improve coupling efficiency, the fiber end is often processed into micro-structured shapes such as spherical, conical, or parabolic.

2.Indirect Coupling: The laser is coupled to the fiber through a lens. The lens can be a single lens or a system of multiple lenses, with various types such as cylindrical lenses, spherical lenses, or hemispherical lenses, each offering different combinations and uses.

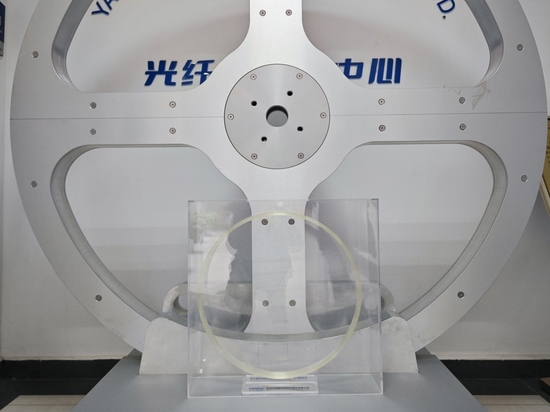

In practical applications, energy transmission fiber typically appears in the form of energy transmission cables, and is often used in conjunction with high-power output heads, bundled connectors, and other energy transmission components. The mainstream output head interface on the market today is the QBH (Quartz Block Head) type, proposed by the Swedish company Optoskand AB. It includes a water-cooling module and can transmit high-power lasers (>5 kW average power). With advancements in manufacturing, commercial high-power energy transmission cables using QD or Q+ interfaces are now capable of transmitting laser powers of tens of kilowatts.

Summary

The primary function of large-core energy transmission fibers is to serve as a medium for laser transmission. With the rapid development of the laser industry, especially the fiber laser technology representing the third generation of lasers—currently, industrial-grade fiber lasers in China can stably output up to 100 kW[10]—a new era of laser applications has begun. Meanwhile, the development of energy transmission fiber has been invigorated by the demands of the all-optical communication network.

Looking ahead, the main direction for the development of energy transmission fiber will still focus on two aspects: higher transmission efficiency and higher transmission power. Higher transmission efficiency will primarily involve breakthroughs in coupling and connection technology for energy transmission fibers. Higher transmission power can be achieved by optimizing existing energy transmission fibers or designing entirely new fiber structures. Additionally, research into new materials, especially those that can better handle infrared wavelength laser energy transmission (as current silica glass materials are ineffective for this), will be essential for further advancements.