#White Papers

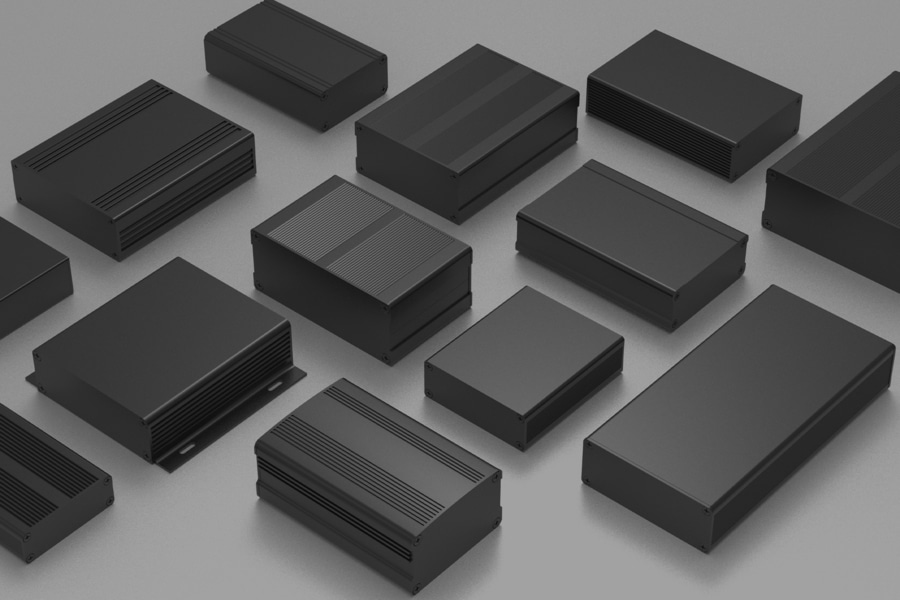

What are the features and benefits of using an aluminum enclosure

Aluminum enclosure have excellent performance and high strength.

The aluminum enclosure has high compressive strength and is not easy to be damaged, so that the safety of internal devices and circuit boards is reliably guaranteed, and it is convenient for storage, transportation and use.

The processing performance of aluminum enclosure is excellent. Yongu’s processing technology is mature, and the CNC high-precision machining of the chassis can be continuous and automated enclosure. And the aluminum enclosure has good ductility and strength, can be rolled into various sizes, and can be punched, rolled, stretched, welded to form aluminum enclosure of different shapes and sizes.

Aluminum enclosure has good protection function. The waterproof level of yongu’s aluminum housing can reach ip68, and its waterproof and dustproof performance greatly exceeds that of other types of casing materials. This has a very good protective effect for outdoor and underwater operations.

The aluminum enclosure is recyclable repeatedly. As a packaging material, aluminum is generally made into aluminum plates, aluminum blocks, aluminum foils, and aluminized films. Aluminum plates are usually used as lidding materials; aluminum blocks are used to make extruded and thinned and stretched cans; aluminum foils are generally used for moisture-proof inner packaging or to make composite materials and flexible packaging.

The aluminum enclosure of yongu is a kind of enclosure that is formed by using aluminum alloy material to achieve the application of placing instruments, tools, measuring tools, etc. The main body of the casing is made of high-quality aluminum alloy profiles, which have the characteristics of reasonable design, solid structure and beautiful appearance. It is an ideal casing for high-end instruments.