#Industry News

The Difference Between Anodizing And Electroplating

yongu-group

Aluminum oxide anodizing treatment is one of the methods of metal surface treatment. A material protection technology that forms a film layer on the surface of the metal material as the anode by applying an external current in a specific electrolyte. Most metal materials (such as stainless steel, zinc alloy, aluminum alloy, magnesium alloy, copper alloy, titanium alloy) can be anodized in a suitable electrolyte.

Through anodizing treatment, the surface of the metal material can be given a beautiful appearance, good corrosion resistance, wear resistance, insulation and other functions, so as to meet different design requirements.

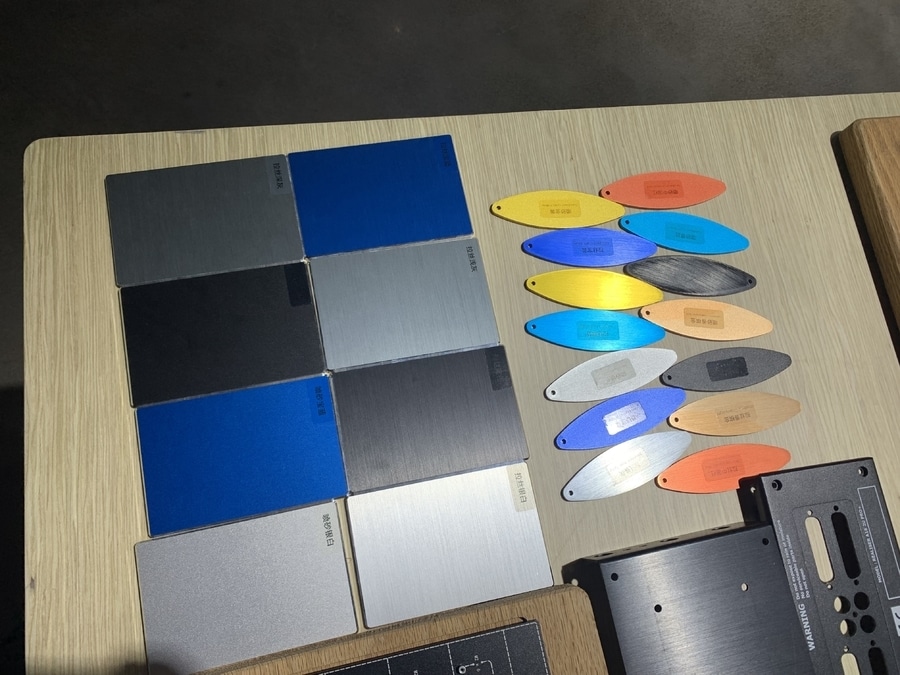

All of Yongucase's electronic equipment enclosure need to undergo anodizing process. This process needs to be very careful. If a little bit is not done well, all of them will be remade. We have high standards for our products and provide our customers with the most perfect enclosures

At present, the most widely used is the anodization of aluminum. Because the oxide film of aluminum has a fine structure, good adsorption, and is not easy to fall off, a fine oxide film is plated by anodizing process to protect it from continuous oxidation.

There are many anodizing processes for aluminum materials, including ordinary anodizing, hard anodizing, and ultra-low temperature hard anodizing. In particular, hard anodizing is widely used in pistons, cylinders, cylinder liners, hydraulic presses and turbines, steam valves, gears, firearm parts, clutches, brake discs and other hard wear-resistant and corrosion-resistant aluminum alloy parts on the surface treatment.

Electroplating is one of the methods of surface treatment of metals and non-metals; as long as they undergo reasonable pretreatment, various metal substrates and some non-metallic materials can be electroplated (for example, ordinary leaves can also be plated with reasonable pretreatments). various electroplating). Different from anodic oxidation, electroplating uses the material to be plated as the cathode, the same metal material as the coating metal is used as the anode (some insoluble anode is also used), and the electrolyte is a solution containing the metal ions of the coating; the input between the anode and the cathode is certain. After the current, due to the charge effect, the metal anode ions move to the cathode, and get electrons at the cathode and deposit on the material to be plated.

At the same time, the metal of the anode dissolves, and the metal ions in the electrolyte are continuously replenished (when insoluble anode plating is used, the salts containing the metal ions of the coating should be replenished in time).