#Industry News

TORQUE SENSORS FOR EVERY APPLICATION

SENSITIVE MEASUREMENTS FROM ROTARY SWITCHES TO ENGINE TESTING

Torques have to be measured in both production and assembly, and again in quality control. burster – the precision measurement technology specialists (see company boxed text) – offer a range of sensors starting with the smallest torques of a few tenths of one Nm, e.g. for quality assurance of rotary switches, all the way up to torques of 1,000 Nm for testing engines. The model 8661 torque sensor, for example, is available in different sizes, beginning with sensitive measurements of 0 to 0.02 Nm, e.g. to determine a breakaway or friction torque, and for speeds up to 25,000 rpm. The largest size can measure up to 1,000 Nm. It is therefore suitable for (performance) testing large engines and gearboxes. Common to all measuring ranges is a very low linearity deviation of less than 0.05 % of full scale. The specialists also offer solutions for special tasks. These include dual-range sensor models with high precision in both measurement ranges. For example, this means that a low steady-state load torque can also be measured with the best possible accuracy on test specimens that have a high starting torque. The sensors’ robust construction and optional features such as a tare function or filter and average value settings can open up further applications, including in price-sensitive or difficult conditions.

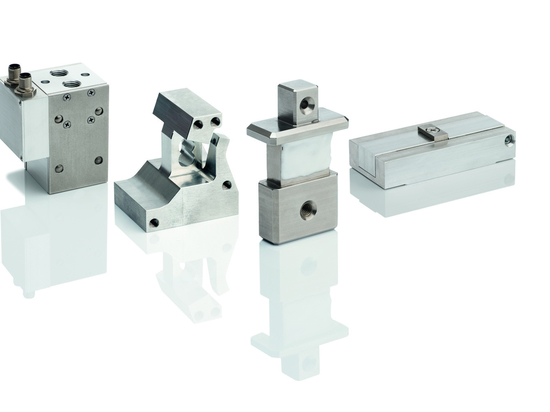

The right sensor for every task

In-house manufacturing enables individual modifications to both the mechanics and the electronics. Special OEM requirements can be quickly implemented. A mounting block simplifies alignment so it is easy to change the sensor frequently. The measured values – torque plus angle and speed measurement, depending on the model – are output as an analog signal with 0 ... ±10 V DC or via USB. The DigiVision software allows up to 1,000 measurements per second to be read out, displayed graphically, and stored. Alternatively, drivers are available for integration into LabVIEW, DASYLab or proprietary software. With DIGIFORCE® process control units, measurement programs for various processes can be implemented flexibly. All torque sensors can be supplied with DAkkS/WKS calibration certificates. Our own accredited calibration laboratory can produce test and calibration logs for existing sensors on request.

About burster

burster supplies measuring technology ranging from individual sensors to system solutions. Its customers are mainly in mechanical and plant engineering, automation, the automotive industry and its suppliers, electrical and electronic engineering and the chemicals industry. The range includes measuring instruments and testers as well as standard sensors for mechanical and electrical measured values, such as load cells, pressure, torque and displacement sensors, milli and mega ohmmeters, and resistance decade boxes. In addition, individual custom OEM solutions are possible, including for many other sectors and future or niche markets such as medical engineering and biotechnology. Many years of experience in designing and building measuring sensors and instruments guarantee optimum solutions every time. Developed and manufactured in Germany, burster sensors, amplifiers and transmitter modules, precision instruments and measuring systems for sensor signal processing are shipped to customers all around the world.