#Product Trends

Lubricants dispensing

Fast, reliable, compact solutions: easy integration into assembly systems.

Many components that surround us in everyday life are often lubricated: the water tap in the bathroom, our car seat adjustment mechanism, the hinge that opens the oven in our kitchen…

During the assembly processes of these and thousands of other elements, it is necessary to think of greases that allow a smooth sliding of the surfaces for the entire life of the component, as an incorrect or even worse a dispensing failure certainly leads to technical problems or to premature breakages.

How are dispensed the lubricants?

The greases are usually contained in cans, tanks, or drums of various sizes; the dispensing systems suck the lubricant from the original container, feeding specific dosing units under pressure that deliver it, creating points, lines, or thin films on the components.

DAV Tech follower plate pumps of the PP series allow to avoid any transfer of grease from the original drum and guarantee a complete consumption of the container without leaving residues on the bottom, thus avoiding any waste.

The follower plates allow the pump to be perfectly matched to the containers and ensure the absence of contamination between the lubricant and the surrounding environment and, furthermore, prevent pump cavitation and the formation of air pockets.

Hoses of various sections and lengths then feed the volumetric dosing heads of the DAV series.

These metering valves are of the volumetric type, they are therefore composed inside with an adjustable volume chamber which fills and empties at each cycle; this technology allows to obtain accurate dispensing not affected by pressure, viscosity, and temperature of the grease.

The filling and emptying of the volumetric chamber can be objectified by sensors and take place only if the valve is correctly fed by pressurized grease; this effectively makes the dispensing process objectified.

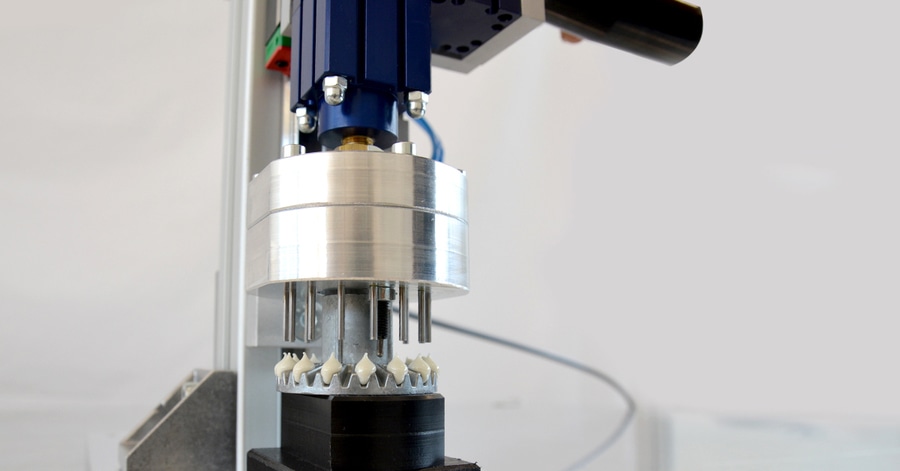

The dispensing valves of the DAV series can also be equipped with specially-made terminals for dispensing on several points at the same time, or with spray terminals that allow you to create a thin film of grease in the area involved in dispensing.

They can also be integrated on contactless dispensing systems where, by means of motors, the heads are rotated and thus create a uniform bead without coming into contact with the component itself.