#Product Trends

GreCon wood chip separation (CHIPINSPECTOR) identifies rubber particles in raw material flow

For the first time ever, rubber can now also be reliably recognised and eliminated in the wood chip flow. The wood chip cleaner CHIPINSPECTOR irradiates the complete raw material flow by means of a combination of low and high energetic X-radiation. For the first time, also materials with the same area density such as, for example, wood and rubber can be reliably differentiated using this technology through the material-specific absorption behaviour of organic materials.

As the raw material is irradiated, it is possible to identify contamination in the material flow independently of the composition of the surface or the moisture content of the raw material. The identification of the impurities also works for thick layers; with the CHIPINSPECTOR, it is not compellingly necessary to move into the thinnest position. Recognition is secure even if the impurities are covered by wood chips. Through reliable identification and exfiltration of bits of rubber before defibration in the refiner, the risk of contamination of the board through rubber particles on the surface is significantly reduced.

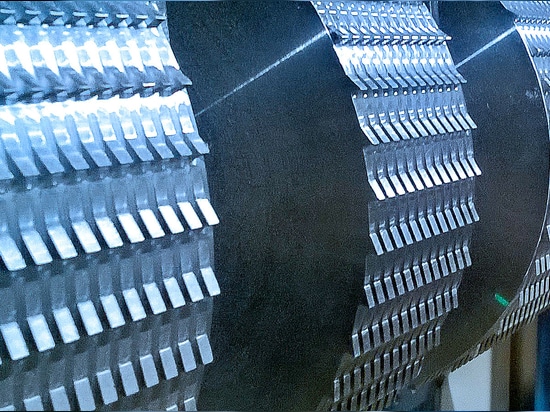

Picture: CHIPINSPECTOR - contamination-free wood chips by automatic separation of foreign objects

GreCon - Innovation is our Tradition

Fagus-GreCon Greten GmbH & Co. KG is a privately held company located in Alfeld/Hanover, Germany. The GreCon business unit is the market leader in the development and manufacturing of measuring equipment and fire protection systems for many types of industries - including the wood-based panels industry. The Fagus business unit operates foremost in the development and manufacturing of shoe lasts. The Machinery business unit is the market leader in the production of finger jointing lines and trades under the name Weinig Grecon. All business units operate worldwide and offer customer support on the job-site. The company counts more than 500 employees.