#Industry News

Ultrasonic Sieving Of Fine Vanilla Powder

A global vanilla powder manufacturer invested in a new Sievmaster Ultrasonic System, to achieve a throughput increase of 50% and reduce waste of good product.

Ultrasonic Sieving Vanilla Powder

Farleygreene’s Sievmaster Ultrasonic System enhances the efficiency and throughput of fine vanilla powder, used in the manufacture of food & beverage, cosmetic and nutraceutical products.

Our customer is a leading manufacturer of vanilla powder as well as other aromatics. Consistently delivering high quality products to meet global demand.

Vanilla powder with its diverse application has become an essential ingredient in food & beverage products. Beyond the kitchen, vanilla powder has made its mark in the cosmetic and fragrance industry. Its natural aroma makes it an ideal addition to skincare, perfumes, and nutraceutical product manufacturing.

Our customer is committed to producing the highest quality vanilla powder to meet the rise in global demand, whilst adhering to the evolving industry requirements. Optimising the processing line is paramount when processing large volumes of raw materials, with the aim to improve efficiency and reduce waste.

Whilst sieving bulk vanilla powder, our client experienced clumps of product building on the mesh wires. This was leading to excessive product waste, premature deterioration of their mesh and prolonged stoppage time in the manufacturing process. They sought out our advice to find a Farleygreene solution to customise their sieve system to increase throughput and reduce waste.

Requirement

Our customer sought a solution to help overcome the challenge of their fine vanilla powder product, forming clumps on their mesh rings, during the bulk sieving process.

The customer requirement was to:

• Reduce clumps in product

• Reduce waste of good product

• Optimise their throughput efficiency

• Maintain high quality product

Farleygreene collaborated closely with the vanilla manufacturer to assess their unique challenges and help provide a tailored solution to their requirement using a mixture of customer testing and our long-standing knowledge of sieving.

Solution

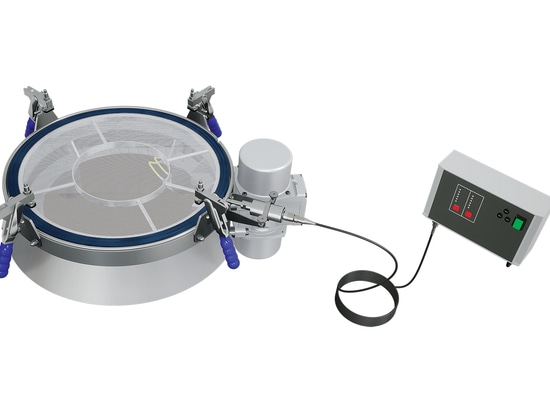

We suggested implementing our Sievmaster Ultrasonic System, which is specifically designed to fit within most Sievmaster sieving machines providing a solution to deblind and fluidise their fine product so that it can be screened more efficiently.

So how does this solution work so effectively? Ultrasonic sieves employ high-frequency vibrations to efficiently separate particles and increase flowability. When applied to the processing of vanilla powder, this technology ensures a consistent particle size distribution, resulting in a more uniform and refined product. Reduction of clumps or uneven textures helps enhance the overall quality, meeting the high standards demanded by our customer.

We carried out tests on their product, with and without the ultrasonics, at our Farleygreene in-house test facility and achieved a favourable result. Keeping our client updated throughout the process and exchanging data, photos and videos to support our findings, in search of the most optimised solution.

Results

Data collected in our testing room showed a dramatic increase in both overall efficiency and throughput. With the addition of ultrasonics achieving an overall throughput increase of up to 50% for vanilla powder – reducing processing time!

Based on the recommendations from testing, this vanilla powder manufacturer has implemented the ultrasonic system into their production line. They managed to increase product yield for their vanilla powder and save time and money.

This ultrasonic system is available with a variety of different options depending on your user requirements and is proving to be a game-changer in the sieving industry of fine products, both wet and dry.

In similar tests carried out at Farleygreene with other more difficult products like rice flour, the throughput was increased dramatically from 144kg/h to 1542kg/h (a 10x increase)!

Enhanced Efficiency

Farleygreene Sievmaster Ultrasonic System significantly improved the efficiency of the vanilla powder sieving process due to faster and more accurate product separation of vanilla powder into the saleable and waste products. Resulting in increased throughput and reduced processing time.

Improved Precision and Quality Control

The mesh screen option selected and fine-tuned vibration settings allowed for precise control over particle size distribution, ensuring consistent quality.

Flexibility and Adaptability

The extensive options available for our sieves offered this customer unparalleled flexibility in working with their specific product. Working alongside Farleygreene, enabled this manufacturer to reimagine their sieving processes, using a tailored ultrasonic system to their desired specifications for vanilla powder.

Easy Maintenance and Durability

A sieve with the ultrasonic feature clears the mesh more effectively by reducing dwell time of the product on the wires. This minimises the wear of the mesh leading to longer-lasting mesh screens and less frequent cleaning.

Cleaning time is also faster because there is less stubborn product caked onto the mesh needing to be removed. By optimising the sieving process, manufacturers can reduce downtime and minimise operational disruptions.

Cost savings

This ultrasonic technology can increase the yield from the raw product, by reducing the waste of good product and resulting in significant cost savings over time. We have demonstrated the value of investing in advanced sieving equipment options to save money in the long term.

Farleygreene sieves have proven to be the best choice for sieving vanilla powder, transforming this manufacturer’s process with our advanced features, testing facility, precision, and efficiency.

Ultrasonics - Key Facts:

• Saves time: The Sievmaster Ultrasonic System, uses adjustable ultrasonic intensity, to enhance the vanilla powder flowability. Breaking down clumps of good product and reducing waste. Ultrasonic technology optimises the bulk sieving process in screening machines, helping prolong the life of mesh rings, reducing cleaning intervals and saving on unnecessary downtime.

• Saves money: With ultrasonics achieving an overall throughput increase of up to 50% for vanilla powder. Making it a compelling investment for manufacturers seeking to elevate their vanilla powder offerings.