#Industry News

Implementation of pyrometer for SNCR control

Flue Gas Temperature measurement

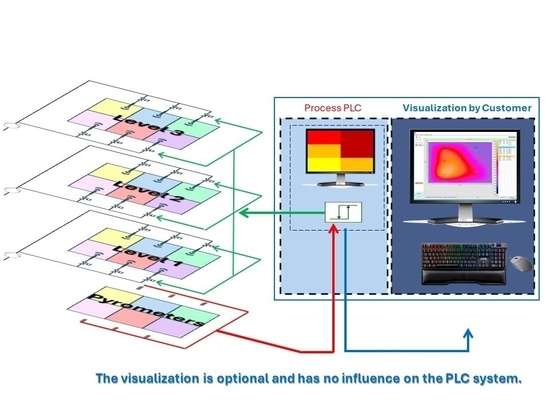

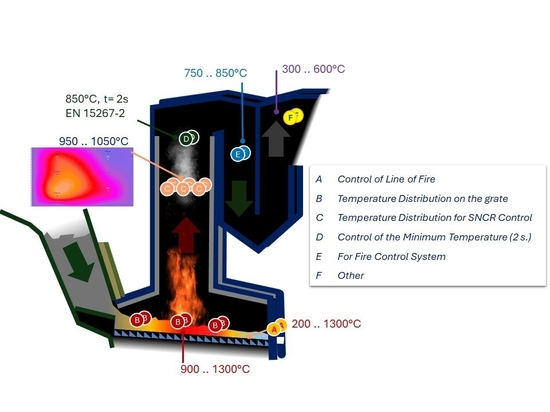

Knowledge of the temperature distribution in the combustion chambers of incineration plants makes it possible to place the SNCR control system in the optimal temperature window, but also to draw conclusions about the quality of the combustion. The use of radiation thermometers (pyrometers) is the least problematic and cheapest way to measure the temperature of the flue gas.

The use of only 6 to 8 pyrometers, combined with the customer's programming of the control system, makes it possible to optimize the SNCR plant and achieve savings by reducing ammonia consumption, among other things.

Task

For optimal operation of selective non-catalytic denitrification (SNCR), maintaining the temperature window between approx. 850 and 1000 °C is crucial. Rapidly changing combustion conditions, e.g. in waste incineration plants, lead to strong spatial and temporal temperature fluctuations in the combustion chamber. Knowledge of the current temperature distribution is therefore necessary for optimal process control.

Solution

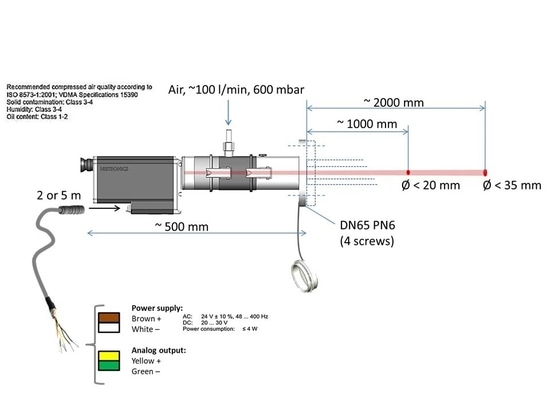

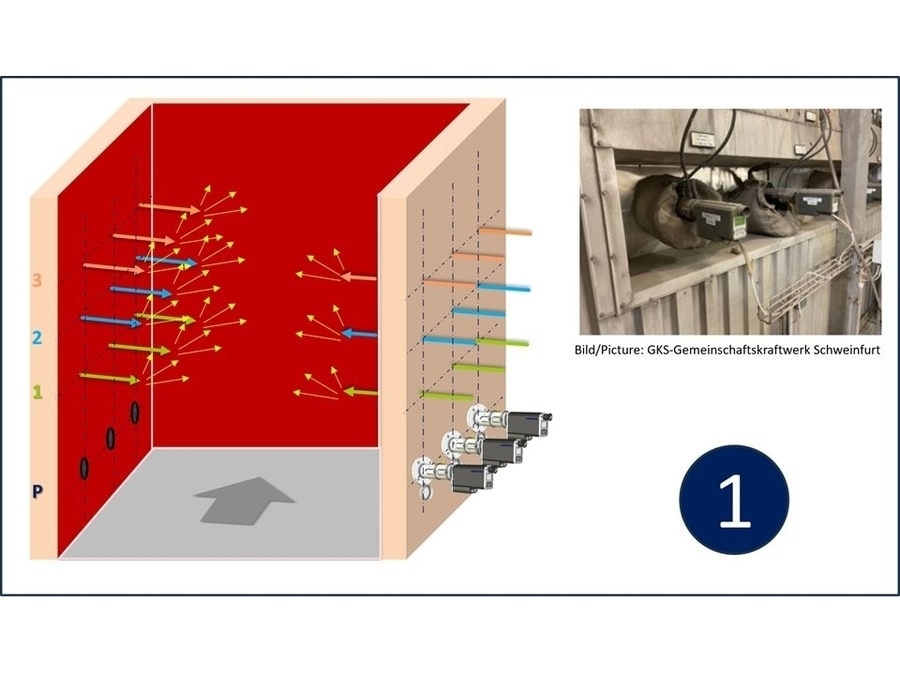

IR radiation thermometers, which use the CO2 emission line to measure the flue gas temperature, are particularly suitable for recording the combustion chamber temperature. The advantage of IR radiation thermometers is their fast response time and ease of use, as they are mounted outside the combustion chamber and only on two walls.

The control system can process the measurements of the pyrometers without an intermediate computer or black box and thus control the ammonia injection. Figure 1 shows a set of pyrometers for SNCR control.