#Product Trends

Basic explanation of HLC stamping knowledge

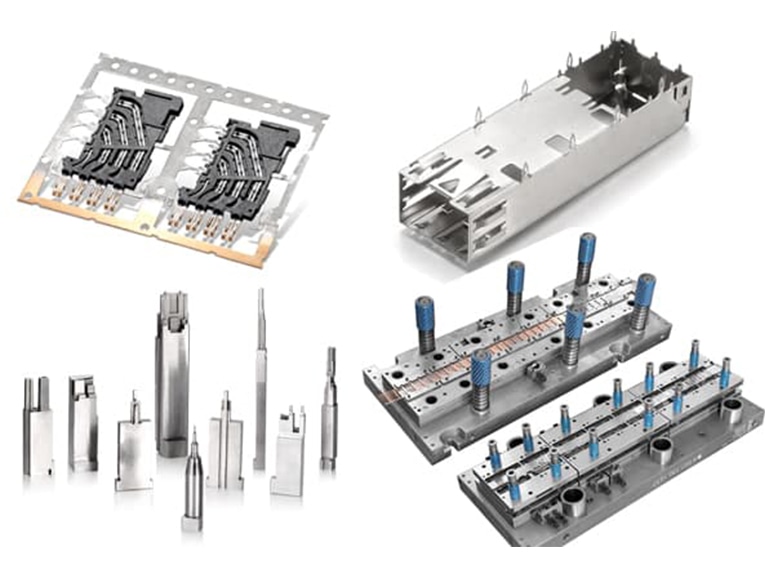

HLC has been specializing in the production of hardware for 15+ years, and briefly explained stamping products, single-punch dies and continuous dies

Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping press, blanking, embossing, bending, flanging, and coining. This could be a single stage operation where every stroke of the press produces the desired form on the sheet metal part, or could occur through a series of stages. The process is usually carried out on sheet metal, but can also be used on other materials, such as polystyrene. Progressive dies are commonly fed from a coil of steel, coil reel for unwinding of coil to a straightener to level the coil and then into a feeder which advances the material into the press and die at a predetermined feed length. Depending on part complexity, the number of stations in the die can be determined.

Stamping divided into Single die and Progressive Die.

Single die: generally consists of a die and a punch or a plurality of die and a plurality of punches, but in the case of a punch, only one punching process can be completed in one pass.

Progressive die: refers to the press in the stamping stroke, using strip-shaped stamping raw materials, using a number of different stations on a pair of molds to complete the cold stamping die of multiple stamping processes at the same time. Once, the belt moves once every distance until the product is finished. The continuous die is in a certain order, in the first stroke of the punching machine, the punching process is completed twice or more at different positions of the workpiece.

Progressive die, the material strip always moves in one direction during the stamping process. The inner strip of the mold is cut into two or more directions, which is called a continuous mold. The feeding of the strip in the mold is called automatic continuous mold. Stamping production chains are used with stamping dies of different processes.

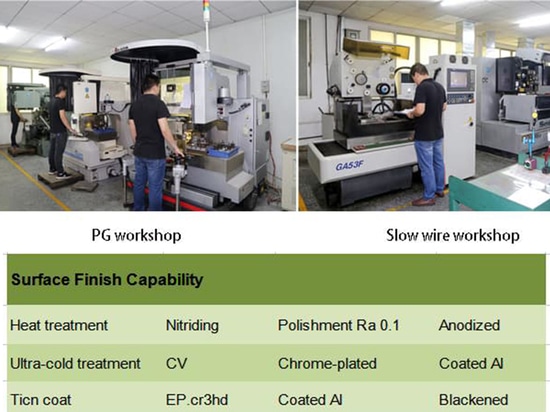

HLC is a professional metal stamping die factory with 15+years experience. We are engaged in the hardware production field for many years, with a professional engineer team and sales department, and IATF16949:2016 certified. We are Focusing on processing with all kinds of materials like aluminum, steel, stainless steel, brass, etc. We can also do surface treatment like Anodizing, Plating, Painting, Brushed, Passivation, Polishing, Grinding, Laser Carving, Screen Printing, etc.

Please contact us anytime for a quote on our metal stamping, deep drawn stamping and other comprehensive metal fabrication services.Please send us your blueprints, sketches and samples for our prompt and courteous quotation.