#Industry News

What is Nickel Plating

Types of Nickel Plating

Nickel is a shiny metal with a light gold tint, commonly used for plating through an electrochemical process. In nickel plating, nickel ions from a solution containing nickel salts (like nickel sulfate or nickel chloride) are deposited onto a part’s surface using an electric current. The part, acting as the cathode, receives a smooth, even nickel coating as ions move from the solution.

Types of Nickel Plating

1.Decorative Nickel Plating

Thin layers (5-15 microns) are applied to enhance a product's shine and appearance. Often combined with chrome plating, it’s popular for home appliances, furniture accessories, and other decorative items.

2.Protective Nickel Plating

Thicker layers improve resistance to rust, wear, and oxidation, making it suitable for chemical equipment, instruments, and outdoor applications.

3.Electroless Nickel Plating

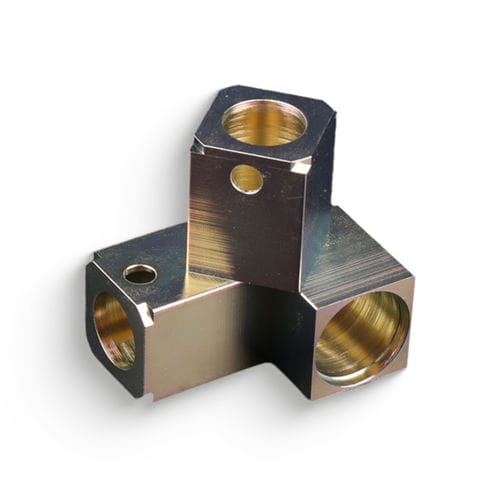

Unlike traditional plating, this process uses a chemical reaction to deposit nickel without electricity. It produces a uniform coat, even on complex shapes, and provides excellent corrosion resistance and hardness. It’s widely used in aerospace, automotive, and precision instruments.

Benefits and Drawbacks

Nickel plating not only protects against rust and wear but also gives products a shiny, polished look, making it common for hardware, electronics, and car parts. Electroless nickel plating is especially effective for irregularly shaped parts. However, it can be costly, particularly for electroless methods, and requires careful waste treatment to minimize environmental impact. Additionally, the part's surface must be clean and smooth to ensure a proper and even coating.