#Industry News

Electroless Nickel Plating Process VS Electrolytic Nickel Plating Process

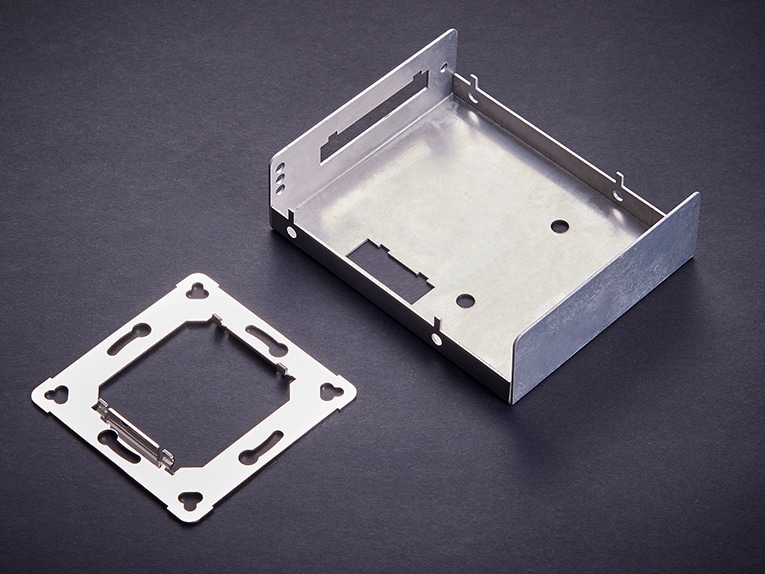

Surface treatment: Nickel plating process

The electroless nickel plating process (EN) has several distinct advantages over the traditional electrolytic nickel plating process. The primary difference with the nickel plating process is that EN does not require the application of an external electrical current to drive the deposition as does electrolytic nickel. Rather, EN uses a chemical reducing agent within the solution chemistry which results in nearly uniform deposition on all surfaces that are wetted by the EN chemistry. Since the electrolytic nickel plating process requires the application of an externally applied DC current, the deposit tends to be non-uniform with excess deposit on the edges or corners (high current areas) of the part.

An additional difference is that EN is an amorphous alloy of nickel and phosphorous. The addition of phosphorous provides the deposit with more corrosion resistance, less magnetic properties (high phosphorous varieties) and a lower coefficient of friction than electrolytic nickel. The application of post-plate heat treatment of EN causes the formation of nickel phosphides at grain boundaries which further hardens the deposit to as high as 69 Rc. The plate is uniform across diameters, across threads and in dead end holes. This property often eliminates the need for post-plate machining on critical dimensions.