#Industry News

punching process

Precision stamping enables manufacturing

In today's manufacturing industry, stamping process plays an irreplaceable role in production, especially punching technology, is becoming an important part of product design and manufacturing. Whether in automotive, home appliances, electronic equipment or building materials, the punching process is bringing significant benefits to manufacturers.

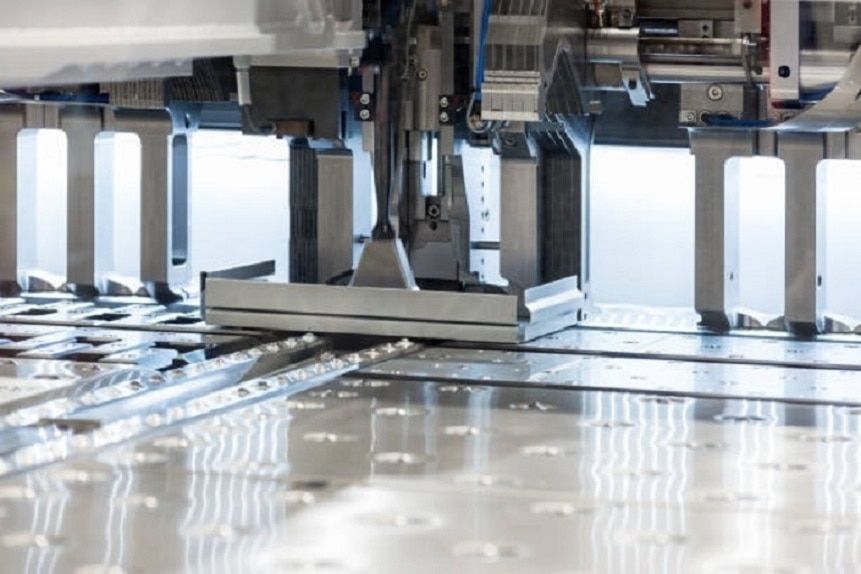

The punching process uses custom molds on sheet metal to punch out precise holes, dents or bumps, enabling highly consistent and repeatable production. This process can not only efficiently process high-volume parts, but also ensure the accuracy and quality of the product, thereby reducing production costs and waste of resources.

In the automotive industry, the punching process is used to make body parts such as doors, hoods and chassis. The holes and bumps in these components can help improve the aerodynamic performance of the vehicle, while also providing an important assembly point. In the field of home appliances and electronic equipment, the punching process can add a beautiful appearance and ventilation holes to the housing and panel.

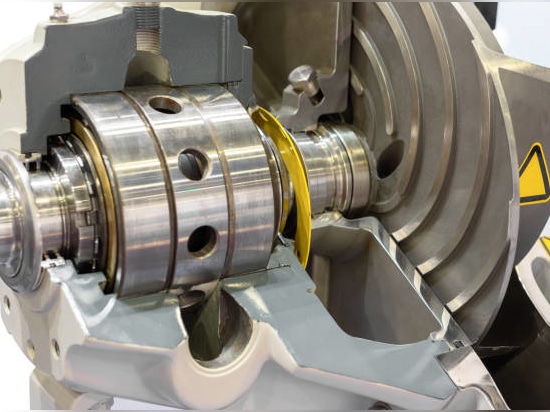

With the continuous progress of technology, the punching process is also constantly innovative. The application of modern CNC punches and high-precision molds makes the punching process more accurate and efficient. At the same time, engineers are constantly exploring more complex shapes and designs to make the punching process more flexible and creative.

As an important part of the stamping process, punching process is increasingly being paid attention to and applied by the manufacturing industry. Its efficient and precise characteristics not only meet the needs of mass production, but also bring improvements to the appearance and performance of products. With the continuous innovation of technology, the punching process will continue to play an important role in the future, promoting the development of the manufacturing industry.