#Industry News

stamping die

Understanding the Key Components of Stamping Dies

Stamping dies are essential tools in the manufacturing industry, enabling the production of precision metal parts used in a wide range of applications. To gain a deeper understanding of these vital tools, it's crucial to explore their key components and how they contribute to the stamping process.

Stamping dies, also known as press dies or metalworking dies, consist of several integral parts that work in harmony to shape, cut, or form metal sheets into the desired components. Let's take a closer look at these essential components:

● Die Block: The die block is the primary frame of the stamping die, providing structural support and rigidity. It holds all the other components in place and absorbs the tremendous forces generated during the stamping process.

● Punch: The punch is the upper part of the die set, responsible for delivering a downward force onto the metal sheet. It comes in various shapes and sizes, depending on the desired outcome. The punch's precision and alignment are critical for achieving accurate results.

● Die Cavity: The die cavity, also known as the die impression or die nest, is the lower part of the die set. It forms the negative shape of the final part and accommodates the material being stamped. The accuracy of the die cavity determines the quality of the finished product.

● Strippers: Strippers are used to help remove the finished part from the punch after each stamping cycle. They ensure that the part is cleanly separated from the punch, preventing any damage or deformation.

● Guide Pins and Bushings: These components provide alignment and precision during the stamping process. They ensure that the punch and die cavity meet accurately with each cycle, minimizing wear and tear and maintaining consistency in the production process.

● Die Springs: Die springs are essential for controlling the return of the punch after each stroke. They absorb energy during compression and release it during expansion, ensuring a smooth and controlled operation.

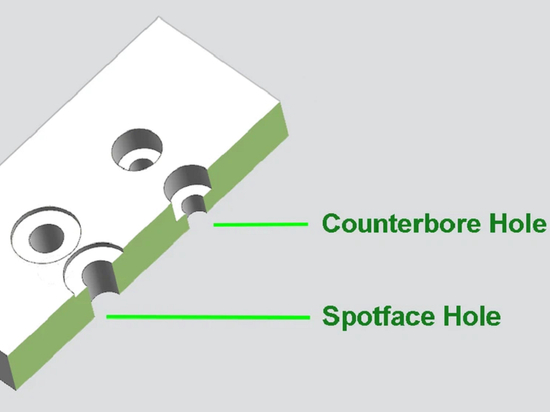

● Pilots and Pilot Holes: Pilots are used to guide the punch into the correct position before the stamping process begins. Pilot holes in the metal sheet provide a reference point for accurate placement.

● Shut Height Adjustment: This feature allows for fine-tuning the distance between the punch and die cavity, accommodating different material thicknesses and ensuring precise stamping results.

Understanding these key components of stamping dies is vital for optimizing the manufacturing process, achieving consistent quality, and minimizing downtime. Stamping die design and maintenance play crucial roles in the overall efficiency and success of metalworking operations.

As the manufacturing industry continues to evolve, innovations in stamping die technology and design are driving increased productivity and accuracy. Staying informed about the latest developments in this field is essential for companies striving to remain competitive and meet the demands of today's markets.