#Industry News

What Exactly Is Anodizing? And How It Works?

Anodizing

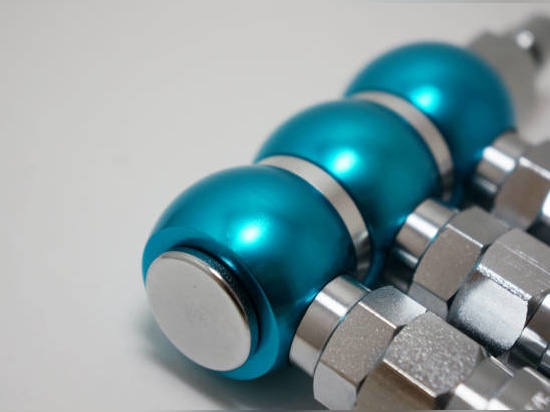

Anodizing is a highly specialized surface treatment process that offers numerous benefits to metal parts, particularly aluminum. This process not only enhances the corrosion resistance and wear resistance of the parts but also significantly improves their appearance. For businesses operating in the custom metal parts manufacturing industry, anodizing is essential for improving product lifespan and aesthetic appeal, thereby gaining a competitive edge in the market. By understanding the intricacies of anodizing, you can gain valuable insights into how the industry has evolved over time and identify opportunities for innovation and growth.

# What Is Anodizing?

Anodizing is an electrochemical process that converts the surface of a metal into a durable, corrosion-resistant, anodic oxide finish. Unlike surface-level treatments like paint or plating, anodizing is integrated with the underlying metal, making it highly effective in enhancing its properties.

The roots of anodizing can be traced back to the early 20th century when Charles W. Watts patented the process in the United States in 1923. Originally, the primary goal of anodizing was to enhance corrosion resistance in aviation and marine applications. However, over the years, the process has evolved and found diverse applications across various industries.

To learn more about anodizing or to inquire about our services, please visit our website.Click the link below to access more information about this blog. If you would like to request a free, no-obligation quote, please feel free to contact HLC.