#Industry News

What Is Die Casting

Your Definitive Guide In 7 Sections

Die casting is a casting method in which molten metal is poured into a pressure chamber and quickly filled into the cavity of a mold to solidify the alloy under pressure, forming a casting. Its main characteristics, which set it apart from other casting methods, are high pressure and high speed.

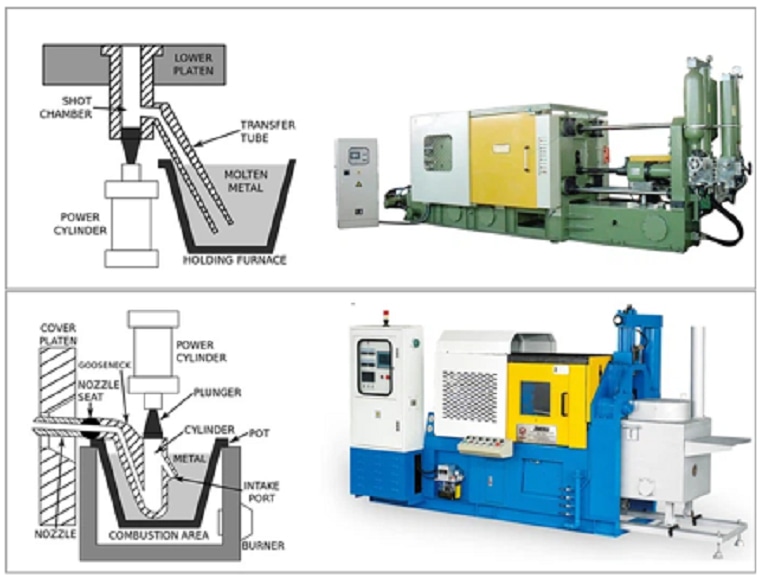

Die casting is a diverse casting process. Based on the die casting equipment, it can be categorized into hot chamber die casting and cold chamber die casting, which is the most common major classification.

Aluminum die casting is favored for its lightweight properties, exceptional thermal conductivity, and resistance to corrosion. At present, almost all automobile transmission case, clutch case, water pump case, carburetor case, etc. are aluminum alloy die castings.

Aluminum alloy parts can be recycled, the recovery rate is not less than 85%, and 60% of aluminum alloy used in automobiles comes from recycled waste.

Zinc alloys have a low melting point, approximately 385°C (725°F), making them exceptionally easy to cast. Zinc alloys are more malleable compared to other metals like aluminum. Thanks to their superb surface finish, zinc alloy parts usually do not need additional machining or finishing operations. This reduces both production time and costs.

For more information, please visit hlc website. We will serve you warmly and professionally.